Safety Inspection of Drum

Safety Inspection of Drum

1. Safety Inspection & Scrapping Standards

① The fixing device of the tail end of the wire rope on the drum should have anti-loosening or self-tightening performance. The fixing condition of the tail end of the wire rope should be checked once a month.

② The end of the multi-layer winding drum should have a flange. The flange height should be 2 times higher than the outermost layer The diameter of the wire rope or the width of the chain, the single-layer winding single-unit drum should also meet the above requirements.

③ When the drum used for the lifting mechanism and the luffing mechanism has no structure that penetrates the supporting shaft in the drum, it is advisable to use steel.

④ When the wire rope on the drum is released at most during operation, the remaining part on the drum should be wound at least 2-3 times in addition to the number of turns for fixing the rope tail to avoid stress on the rope tail pressure plate or wedge sleeve and wedge block.

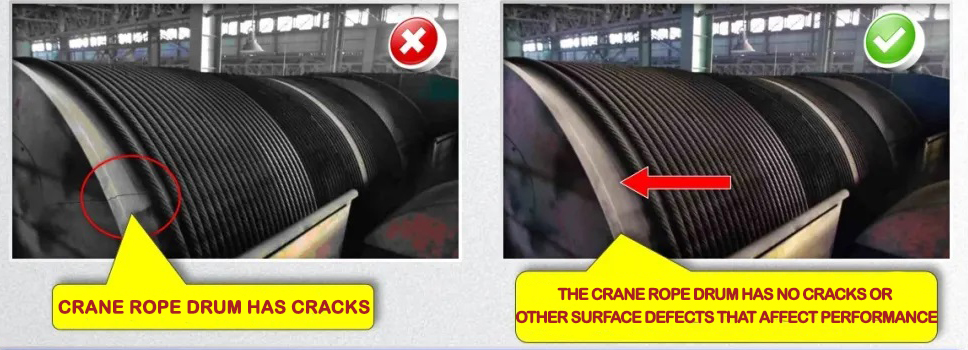

⑤ When the drum has cracks or the drum wall wear reaches 20% of the original wall thickness, it should be scrapped.

2. Safety Inspection Points & Methods

The fixing device of the tail end of the wire rope on the drum is usually fixed by a pressure plate or a wedge block. During the inspection, it should be checked whether each pressure plate presses two ropes at the same time. It is not allowed to press only one rope; at least two pressure plates are used for each rope end. The pressure plate bolt should have an anti-loosening device, which can be a spring washer or a double nut. When using a wedge block for fixing, the taper of the wedge block and the wedge sleeve should be consistent so that the force of the clamped part of the wire rope is uniform.

When checking, the oil stains should be removed first, and the wall thickness δ₀ of the unworn part of the drum wall should be measured with a caliper, and the diameter D₀ of the unworn part of the drum should be measured with a caliper, and then the diameter D of the most severely worn part should be measured with a caliper, which should meet the following requirements:

Wear △=δ₀-δ=(D₀-D)/2<0.2δ₀

When checking for cracks, the oil stains should be cleaned first, and then checked with the naked eye or a magnifying glass.

The drum shaft is inconvenient to check at ordinary times, so it should be checked during the crane overhaul. During the safety inspection, the shaft should be removed from the drum, cleaned, and visually inspected for cracks. If necessary, non-destructive testing should be performed. If there are cracks, it should be scrapped.

More technical support from us, please contact us.