Wire Rope Drum

Crane Parts

Material: ZG25/ZG35/Q235/Q345

Hardness: HRC45-HT55.

Groove Surface Quench Depth: ≥2mm

Max Diameter: 3000mm

Heat Treatment: Must

Inspection Test: UT and MT

OEM: Available

Spring Driven Wire Rope Drum are mainly used in cranes, stacking equipment or wastewater treatment technology. They are rugged, inexpensive and suitable for mobile equipment without an internal power supply. Motor Driven Wire Rope Drum are used when greater precision and speed control are required

Description

The wire rope drum is a widely used machine in lifting machinery, used to lift and pull heavy materials in construction sites, port piers, factories, and mines.

The wire rope drum is a widely used machine in lifting machinery, used to lift and pull heavy materials in construction sites, port piers, factories, and mines.

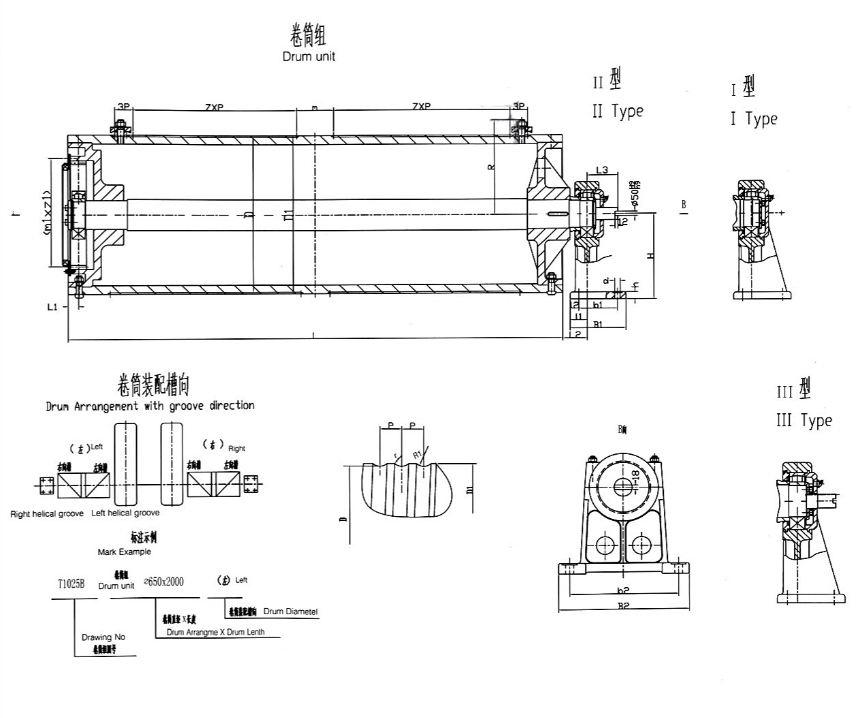

According to the shape: This classification includes smooth drum, spiral groove drum, single drum, double drum, and broken line drum. The smooth drum has a cylindrical surface without any grooves, while the spiral groove drum has grooves that run in a spiral pattern along the length of the drum. Single drum and double drum refer to the number of drums used in a lifting system, with single drum having one drum and double drum having two. A broken line drum is a type of drum with a non-uniform groove pattern, designed for specific lifting applications.

According to the installation and reducer matching: This classification includes take-over reel with gear plate, reel with external gear, reel with coupling, reel with brake disc, and European-style reel. These classifications refer to how the drum is installed and matched with a reducer, which is a device used to reduce the speed of the motor to the required speed of the drum.

According to the matching equipment: This classification includes electric hoist drum, double beam drum group, hoist drum, winch drum, and stereo garage drum. These classifications refer to the different types of equipment that can be used with the crane drum, such as electric hoists, winches, and double beam crane systems.

The different classifications of crane drums can help to identify the specific features and applications of each type of drum. The choice of crane drum will depend on factors such as the lifting capacity, speed, and environment, as well as the specific requirements of the lifting operation.

Technical Specifications

|

Feature and Advantage

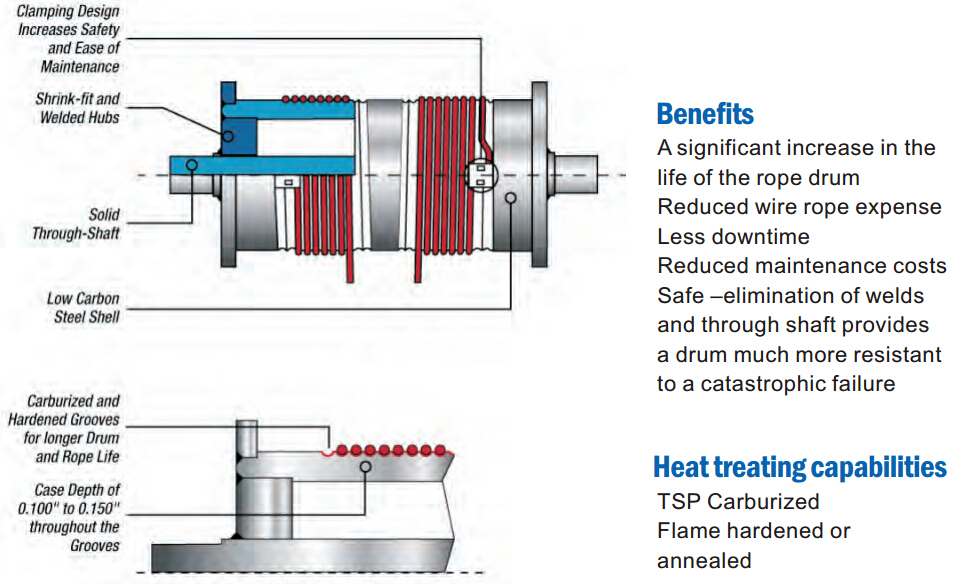

The surface of the single-layer winding wire rope drum is cut with a spiral groove with an arc-shaped section to increase the contact area between the wire rope and the drum body, and to fix the winding position of the wire rope on the drum to avoid the influence of adjacent wire ropes rubbing against each other.

The surface of the drum body of the multi-layer winding drum is usually a smooth surface without spiral grooves, and there are flanges at both ends of the drum body to prevent the wire rope from slipping out. The disadvantage is that the wire ropes are closely arranged, and the layers are stacked and rubbed against each other, which has a great impact on the life of the wire rope.

Among the structural dimensions of the reel, the key dimension that affects the life of the wire rope is the calculated diameterof the reel.

In order to ensure the reliable fixation of the wire rope tail and reduce the stress on the pressure plate or wedge, when the pick-up device is lowered to the lower limit position, in addition to the fixed loop of the wire rope, 1.5 to 3 safety loops should be reserved on the reel.

Known as the load-relief ring, this has been taken into account in the design of the reel. In use, the more loops of the wire rope tail are retained, the smaller the force on the pressure plate or wedge of the rope tail, and the safer it is.

If the lower limit position of the pick-up device is too low and the remaining number of wire ropes on the drum is less than the designed number of safe loops, the force on the tail of the wire rope will exceed the pressing force of the pressure plate or wedge, resulting in the wire rope was pulled off and the heavy object fell.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.