Multifunctional Crane for Electrolytic Aluminum

Special Customized Crane Series

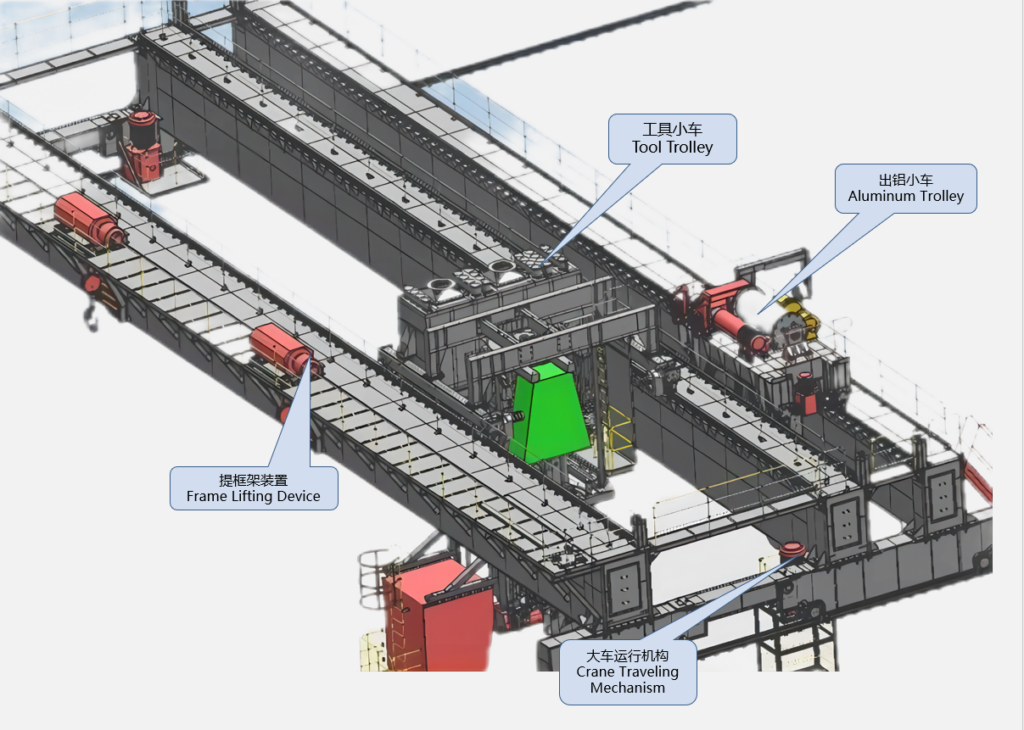

Multifunctional Crane is consists of tool trolley, aluminum trolley, frame lifting device, crane traveling mechanism, etc. Adopted the remote control or rotary cab control and the control type is by PLC, the speed regulation method is variable frequency speed regulation which can be achieved full automatic control.

APPLICATIONS:

ALUMINUM PLANT

INTRODUCTION

Overall Structure

Electrolytic Aluminum Multifunctional Crane is consists of tool trolley, aluminum trolley, frame lifting device, crane traveling mechanism, etc., made of high-strength material.

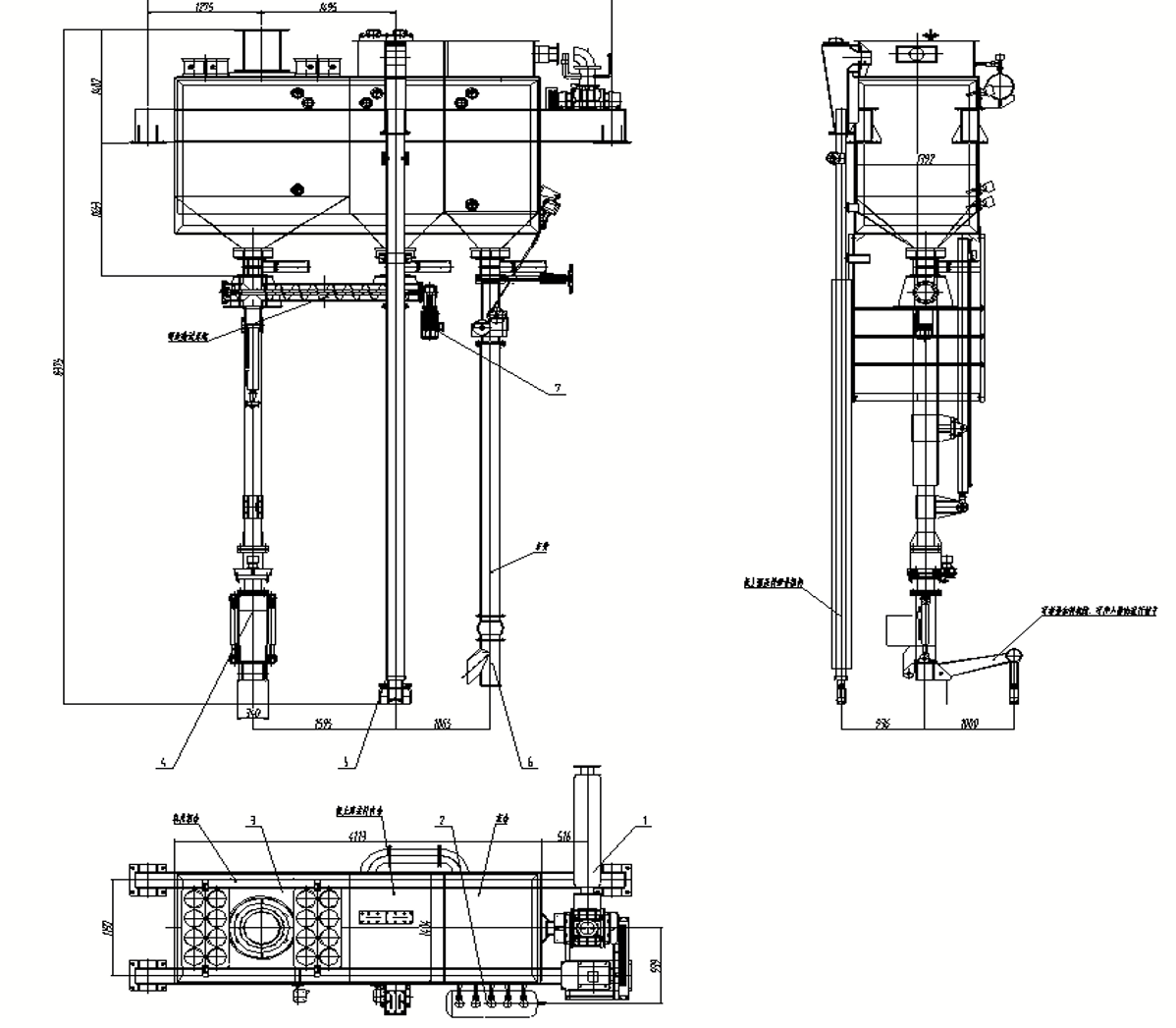

Bridge Structure

Box-type three-main beam or double-main beam form, trolley track with steel rails, off-track layout, box-type end beam, main & end beam adopts lap structure

Main Tools

The main tools include aluminum trolley, shelling mechanism, twisting mechanism, charging mechanism, slag cleaning mechanism

Aluminum Discharging

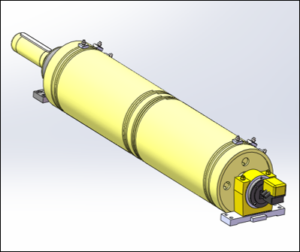

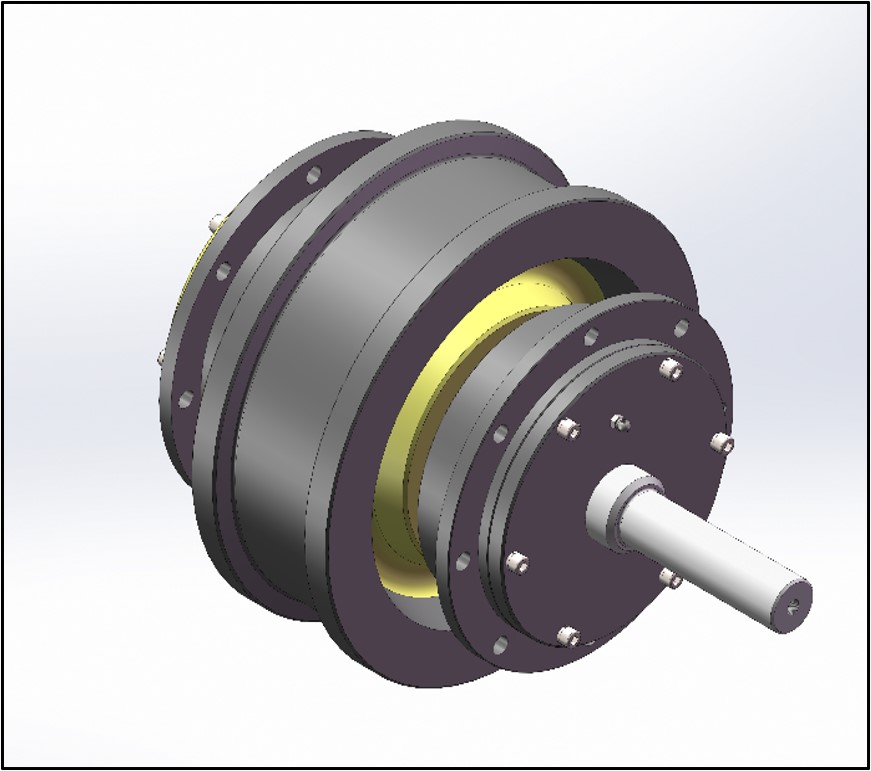

Winch Type, including transmission device, winding system and safety protection device

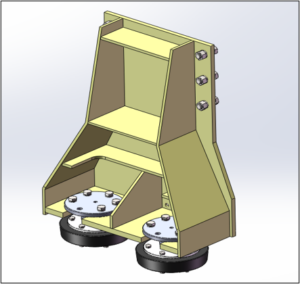

Travelling Mechanism

All Traveling mechanisms of multifunctional crane adopt three-in-one transmission (locking ring)

Operation Type

Remote Control or Rotary Cab Control

Control Type

The control type of multifunctional crane is by PLC, the speed regulation method is variable frequency speed regulation, and full automatic control can be adopted.

MAIN FOUNCTION

Electrolytic Aluminum Multifunctional Crane Main Function as follows,

Charging Mechanism

It is used for filling alumina powder and covering materials and for the regulation of materials after filling. It consists of a material box structure, a feeding pipe and a horizontal conveying system.

The material box structure is welded from Q355B steel. It is recommended that the material box be a closed material box. When the factory adds materials to the material box, negative pressure can be generated in the material box to collect dust. The material silo is equipped with an adjustable hydraulic gate valve.

Media error: Format(s) not supported or source(s) not found

下载文件: https://www.hnsinomac.com/wp-content/uploads/2024/08/Charging-mechanism.mp4?_=1The feeding pipe is a reinforced pipe, which is driven by a hydraulic cylinder and has a foldable nozzle head. The feeding pipe is shared by the alumina silo and the covering silo;

The horizontal conveying system is a screw conveyor structure. After the alumina silo is filled into the tank, the mechanism can directly convey the material in the covering material silo to the feeding pipe to achieve continuous feeding.

Feeding Circulation Mechanism

The main function of multifunctional crane is to collect the covering material before changing the pole, and to add the covering material into the tank after changing the machine. It consists of a sealed material box, a suction pipe, a Roots blower, a bag pulse dust collector, an ash pipe, etc.

Media error: Format(s) not supported or source(s) not found

下载文件: https://www.hnsinomac.com/wp-content/uploads/2024/08/Feeding-Circulation-Mechanism.mp4?_=2

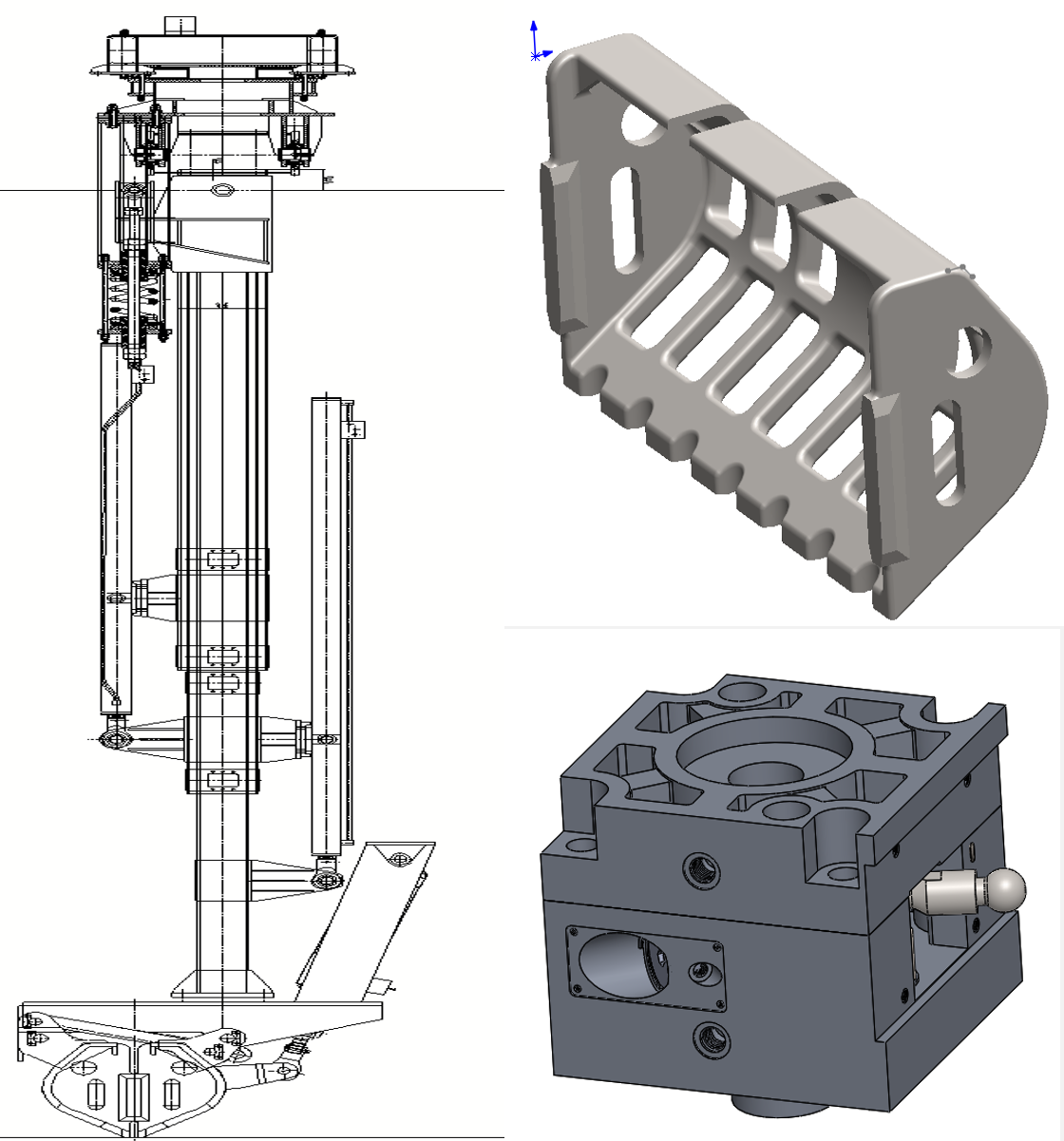

Twisting Mechanism

Replace anode carbon blocks and load and unload small box fixtures. It consists of anode fixtures, screw head parts, lifting guide rods, etc.。

Media error: Format(s) not supported or source(s) not found

下载文件: https://www.hnsinomac.com/wp-content/uploads/2024/08/Twisting-Mechanism.mp4?_=3

1. The anode clamp is a pin-type structure, and its dimensions are interchangeable with the existing clamps. This structure is more accurate and rapid in positioning, helps to achieve automated operation, and can effectively prevent the carbon block from falling.;

2. The screw head is a spline-free direct connection structure, driven by a hydraulic motor. An anti-unhooking device is provided.;

3. The lifting guide rod is driven by a hydraulic cylinder. In order to provide a more stable mechanical structure for automated operation, the shaking amount of the guide rod is controlled to avoid various swings.

Shelling Mechanism

Break up the hard crust around the carbon block.

Media error: Format(s) not supported or source(s) not found

下载文件: https://www.hnsinomac.com/wp-content/uploads/2024/08/Shelling-Mechanism.mp4?_=4

1. The shell breaking mechanism adopts a four-link mechanism, which can effectively hit the middle seam;

2. The shelling machine guide rod adopts a rectangular steel pipe structure, which has good rigidity and small deformation, which is conducive to automation;

3. The shelling mechanism is folded and driven by double cylinders;;

4. The length of the striking head drill rod is shortened, which makes the working space larger and the slot entry more convenient.

Slag Cleaning Mechanism

Cleaning the residue in the electrolytic cell during pole change

1. The bucket body is made of heat-resistant non-stick stainless steel with a heat resistance of up to 1000°C. The bucket body design and materials prevent residues from sticking to the shell.

2. The lifting mechanism is driven by double cylinders, with longer stroke and more stable movement;

3. The opening and closing cylinder is a self-locking cylinder, which can effectively prevent the grab from opening automatically due to its own weight;

4. The grab can be installed at the silo or on the main swing. When installed at the silo, the grab is equipped with a separate swing mechanism;

MAIN PARTS

Set-type reel, Steel Plate Rolling, Short-Axis Structure

The horizontal wheel device can effectively reduce the rail gnawing phenomenon caused by skewed operation

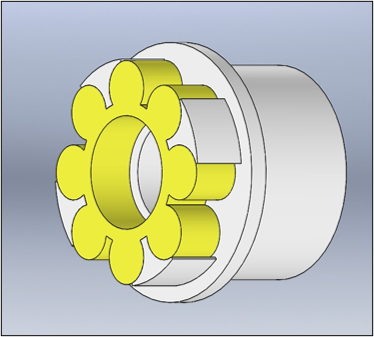

The plum blossom elastic coupling has a buffering effect and can compensate for the large relative offset between the two shafts.

The plum blossom elastic coupling has a buffering effect and can compensate for the large relative offset between the two shafts.

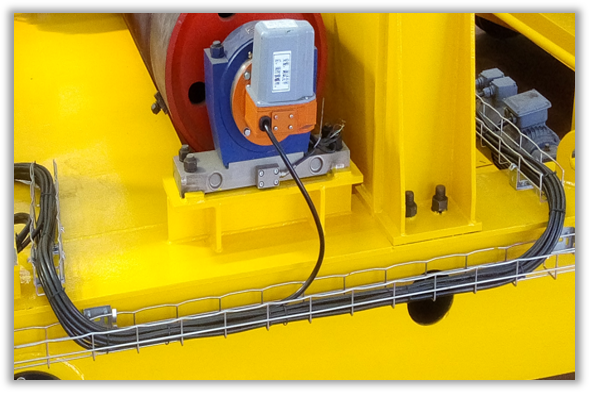

Linkage Table, Operation in the Driver’s Cab, Integrated or Split/Button Remote Control/Joystick Remote Control

The electrical connection adopts international standard heavy-duty aviation plug, protection grade IP65, fast plug and unplug, reliable connection,

SAFETY PROTECTION

Electrical Protection

- Motor Protection

Depending on the motor and its control method, the motor has one of the three protection functions: overcurrent, built-in thermal sensing element and thermal overload.

- Low Voltage Protection

When the main power contactor is powered on again, the main power contactor can only be closed by turning the operating handle back to zero and pressing the “Start” button again.

- Overload Protection

When it reaches 95% of the rated load, a prompt alarm signal is issued. When it reaches 105% of the rated load, a prohibitory alarm signal is issued. At the same time, the lifting mechanism is restricted from rising and can only descend.

- Forward & Reverse Contactor Protection

When the contactor fails, the zero position and the positive and negative contactors are connected in series to control a time relay, and the time relay normally closes the total contactor circuit. After the preset time delay, the main contactor is quickly cut off (main circuit is powered off).

- Zero Protection

When the main power contactor is powered on again, the main power contactor can only be closed by turning the operating handle back to the zero position and pressing the “Start” button again.

- Overspeed Protection

When the lifting speed exceeds the limit, the contact is opened, the main power supply of the vehicle is cut off, and the brake is closed.

- Door Switch Interlock Protection

The passage doors are equipped with door switches (electrical interlock protection devices). When any door is opened, the power supply of the corresponding mechanism of the crane can be disconnected.

- Multi-Point Control Interlock Protection

Each operating point is interlocked to ensure that only one operating point is in working state at any time. Each operating point is equipped with an emergency power-off device.

SIMILAR MULTIFUNCTIONAL CRANE PROJECT

Sinomac Industrial(SANOMAC) is a professional crane manufacturer. We integrate crane research and development, manufacturing, sales, installation and service.