Mobile Conductive Busbar

Cranes Parts

Conductor Material: 99.99% Oxygen Free Copper.

Max Allowable Amper: 200A

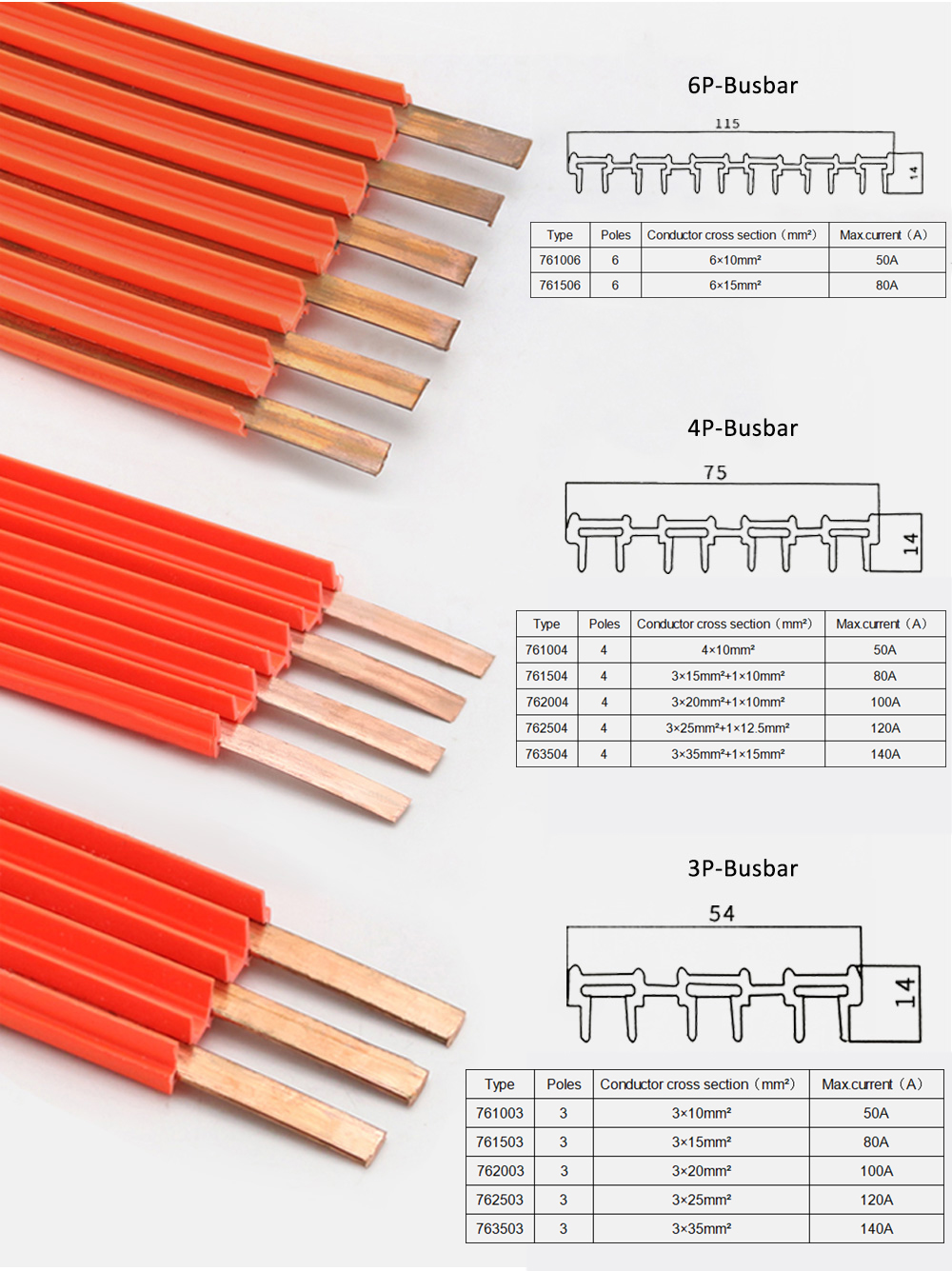

Poles: 3P/4P/6P/Customized

Bending Radius: >750mm

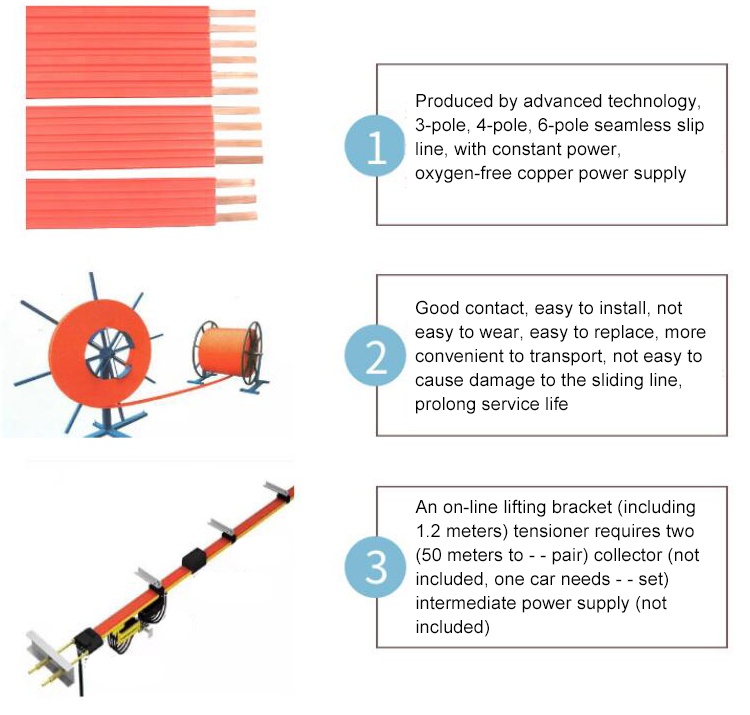

Description

Conductive busbar is using advanced technology 3-pole, 4-pole, 6-pole 99.99% oxygen free cooper conductor with a good conductivity, good contact rate, and good contact. It has an excellent mechanical and electrical properties, which is convenient for installation, not easy to wear, convenient replacement, more convenient transportation.

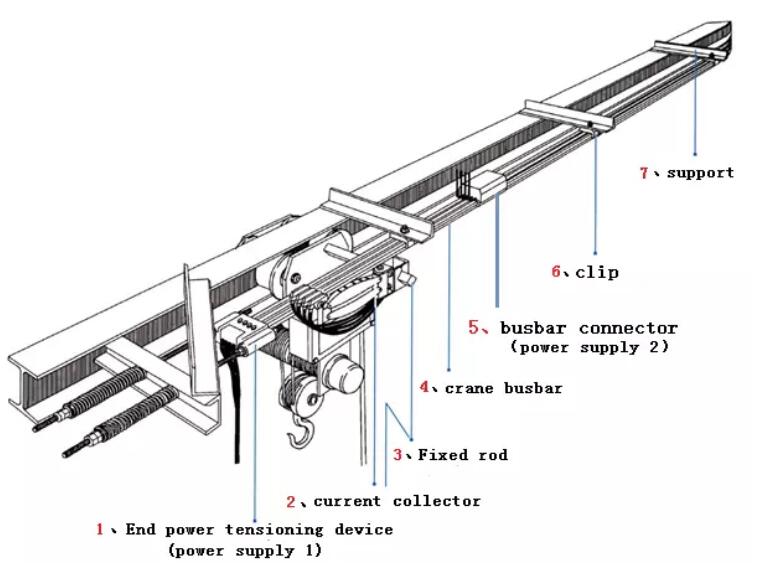

The conductor busbar is including the tensioner, current collector, mobile tow for collector conductor line, hanger clam, bracket, coonector (if applicable).

Product Features

- Non Interface Design: Except for the power supply point, the seamless busbar has no interface. This design reduces the problems of poor contact and wear and extends the service life.

- Safe and Stable: The seamless busbar uses oxygen-free copper to transmit power, which has the characteristics of small voltage drop, high conductivity, and good contact, ensuring the stability and safety of power supply.

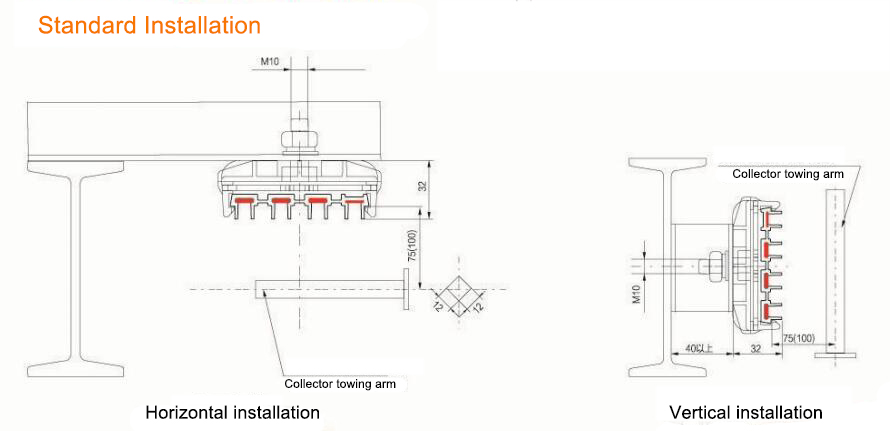

- Easy to Install: Small size, easy installation, suitable for various installation environments, including horizontal installation and side installation.

- Economical and Practical: The seamless busbar is easy to replace, and the transportation and installation costs are low

Parameter Table

Installation & Application

Installation

Horizontal Installation: Suitable for small tonnage cranes, electric hoists and other equipment, with high safety and good application efficiency.

Vertical Installation: Suitable for stackers, AGVs, automation equipment assembly lines, etc., requiring on-site production of side-mounted bottom plates and configuration of tensioning devices and angle steel brackets

Application

With advanced technology, skillful manufacture and beautiful design, the Flexible Insulated Copper Rail is suitable for machinery works, small size steel factory, low power hoisting, cranes, monorails, electric hoists, electric tools, stacking systems and wildly used in the Lifting industry. (ambient temperature is< 55℃)

With advanced technology, skillful manufacture and beautiful design, the Flexible Insulated Copper Rail is suitable for machinery works, small size steel factory, low power hoisting, cranes, monorails, electric hoists, electric tools, stacking systems and wildly used in the Lifting industry. (ambient temperature is< 55℃)

Regular Maintenance

The maintenance and care of seamless busbars is relatively simple, and the following points should be noted:

Regular Inspection: Regularly check the conductivity and insulation performance of the busbar to ensure its normal operation.

Cleaning & Maintenance: Keep the busbar clean to prevent dust and debris from affecting the conductivity.

Replacement of Parts: Regularly replace worn collectors and conductors to ensure the stability and safety of power supply.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.