Ladle Handling Overhead Crane

Overhead crane series

Model: QDY/YZ

Lifting Capacity: 5-320ton

Span: 10.5-31.5m

Lifting Height: 6-30m

Working Duty: A7-A8

Control Mode: Cabin control

Mining, metallurgy, construction, chemical, cement, refractory material, ceramics, etc.

Description

Ladle handing overhead crane is one type of metallurgy crane, which is designed for transporting, pouring and charging hot metal in the process of smelting liquid metal, etc. Also called casting overhead/bridge crane or foundry overhead/bridge crane.

Ladle handling overhead crane is one of the main equipment for steelmaking and continuous casting. It is mainly used to converter molten iron. Transport the molten iron from refining bay to refining furnace or transport it from receiving bay to continuous casting rotary bag.

Ladle handling overhead crane can works under the sever environment of high temperature and dust. The working duty is heavy. The crane after failure may cause big loss and serious consequences. Because of the function of charging melted iron, the ladle crane shall be equipped with main hook and auxiliary hook.

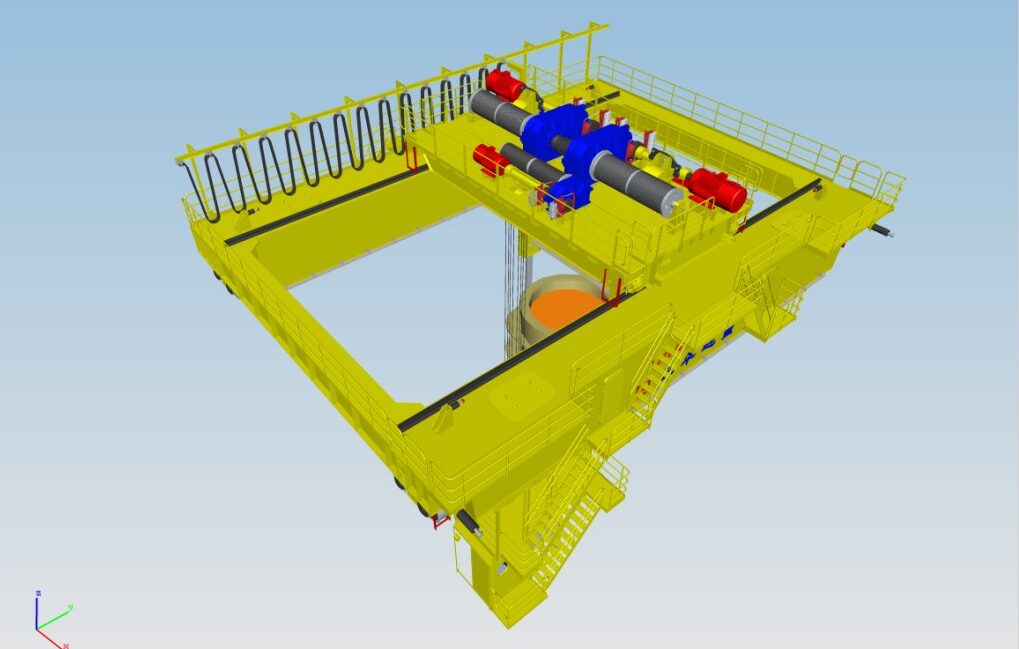

According to the crane structure, the ladle overhead cranes can be classified into double girder ladle handling overhead crane, four girder ladle handling overhead crane, and four girder six rails overhead travelling ladle cranes. The front two types are used for lifting middle and large scale ladles, and the latter one is used for extremely large scale ladles. Sinomac Industrial(SANOMAC) know the hazard and challenge of metals production industry and can offer customized ladle handling overhead crane as per client’s requirements.

Technical Data

| Electrical Panel | Schneider brand for main electrical system. |

| Lifting Motor | SEW/ABB or Chinese Famous Brand. |

| Lifting Reducer | SEW/FLENDER. |

| Lifting Brake | Huawu brand with high quality in China. |

| Speed control | Resistance speed control for lifting; Inverter speed control for CT and LT with three in one motor |

| Power Source | 380V-550v 50/60HZ 3P AC |

| Control Voltage | 220V for cabin control. |

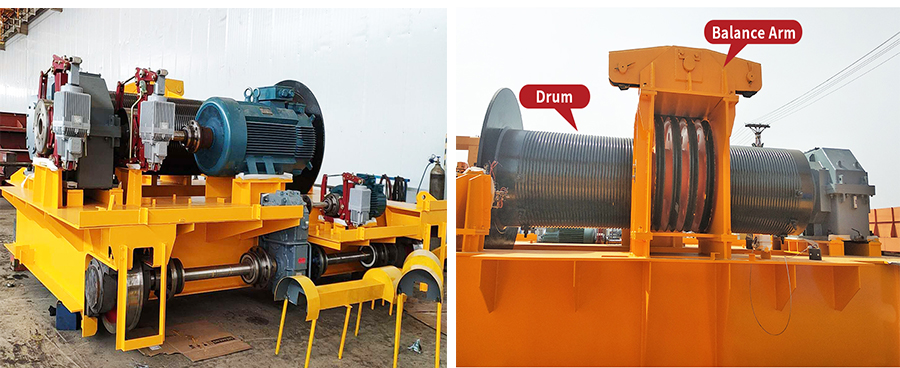

| Power Supply Type | Heavy duty festooning dragging system for trolley power supply. |

| Painting | Sandblast cleaning dispose- 2 Grade, Epoxy primer,

Anti-corrosion painting more than 100um, Corrosion-proof grade C4 |

| Safety Feature | Lifting and travelling limit switches; Emergency Stop; Loss voltage protection; Grounded protection; Overload protection ;Short circuit protection; Overheating protection ; Over speed protection ;Over current protection; Faulted phase protection |

Features

When the lifting mechanism is driven by two sets of driving device which have rigid connection, the power of each motor is not less than 60% of total power. When the crane completes one operating cycle with full load (rated load) by a motor to drive, the power of each motor is not less than 66% of total power. The power of each motor is not less than 50% of total power when adopting planet differential reducer and double motor to drive.

Each set of driving device shall be equipped with two support brakes, braking safety factor of each brake is not less than 1.25. For two sets of driving device which have rigid connection, each set of driving device shall be equipped with two support brakes, braking safety factor of each brake is not less than 1.10. For adopting planet differential reducer to drive, each set of driving device shall be also equipped with two support brakes, braking safety factor of each brake is not less than 1.75.

Laminated hook of ladle handling overhead crane should adopt low-alloy high-strength steel, its strength calculated should not be less than 2.5 corresponding to safety factor of yield point of the steel.

The performance of wire rope for hoisting the molten or heat metal should not be less than wire rope stipulated in standard.

The cab, which work in high temperature environment for a long time (such as metallurgic crane), should be equipped with cooling device, bottom of cab should be equipped with thermal baffle.

The features of ladle cranes are as follows:

- High Working Class: A7-A8 (FEM 4m-5m) for 7×24 hours continuous working

- Cable: Heat resistance silicon rubber insulated cable

- Heat Radiation Protection: insulation layer is added at the bottom of the main girder.

- Control cabin: Closed type, window uses tempered glass and sliding type to protection

- Steel material: High yield strength Q345B steel plate welded as the main structure

- Centralized lubricating system: Reduce maintenance workload, spreading on long travelling, main trolley and aux trolley mechanism.

Product Details

Application

SIMILAR PROJECT

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.