Crane Festoon System

- C TRACK TYPE

- ANGLE STEEL TYPE

- I BEAM STEEL TYPE

- STEEL ROPE TYPE

Festoon System is widely used in industrial and mining enterprises, assembly lines, workshops, laboratories and other occasions, and is used to suspend and move various electric and pneumatic crane system and hoist system.

Description

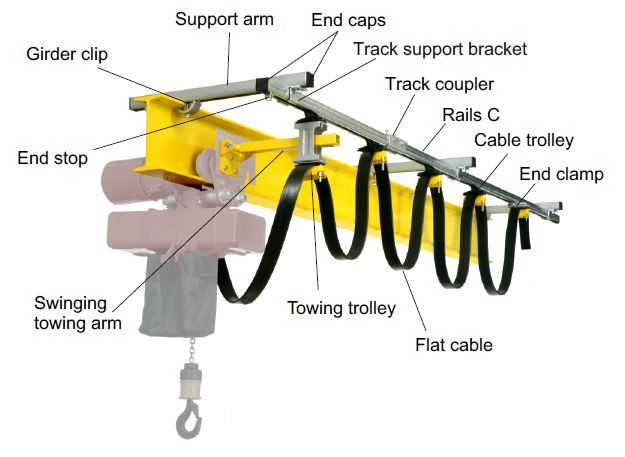

Festoon system is a common mobile power supply solution, which is widely used in the mobile power supply and signal system of lifting and transportation machinery in railway freight yards, port terminals and machinery industries. The system consists of rail track, cable trolleys, cables, and suspension and fixing components. It has the characteristics of simple structure and complete performance.

Product Details

1. Cable Trolleys/Cable Carriers

- These are wheeled devices that move along a track or rail system. They carry the cables and hoses from a stationary source to the moving machinery.

- Cable trolleys are often equipped with rollers or wheels to reduce friction and allow smooth movement.

2. Cables and Hoses

- Festoon systems support various types of cables, including power cables for electrical supply, control cables for communication, and hoses for air or fluid supply.

- The cables and hoses are bundled together and hung from the trolleys.

3. Cable Festoons

- The festoon itself is a structure that supports and manages the cables and hoses.

- It is typically composed of a main track or rail along which the trolleys move, and a series of hangers or loops from which the cables and hoses are suspended.

- The festoon is designed to accommodate the dynamic movement of the cables and hoses as the connected equipment moves.

4.End Stops and Supports

- The system includes end stops at the ends of the festoon track to prevent the trolleys from moving off the track.

- Additional supports and guides may be used to ensure proper alignment and stability of the festoon system.

5.Power Supply System

- To power the moving equipment, festoon systems are often connected to a power supply source, such as a main power line.

- Festoon system can include features like collectors or conductor bars that provide a continuous power supply to the moving equipment.

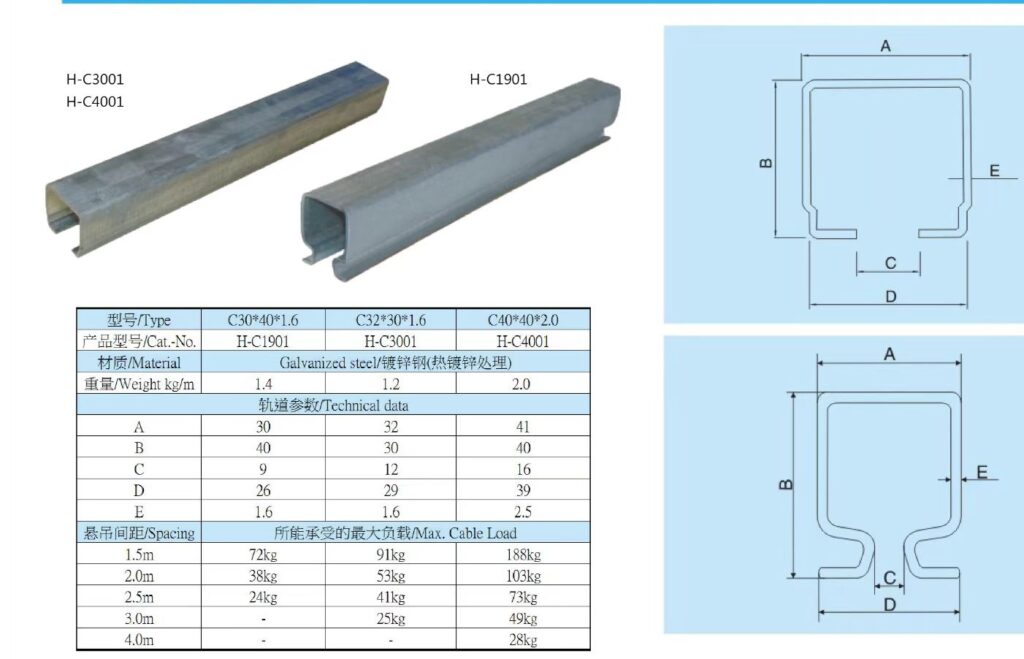

Parameter Table

| Wheels: | Ball Bearing, hardened and galvanized |

| Material: | Carrier Body: Galvanized Steel/304 Stailess Steel |

| Support Saddle: Galvanized steel or ABS | |

| Clamp: Neoprene | |

| Dowel:Seamless brass tube or galvanized steel | |

| Other Hardware:Galvanized steel/304 Stainless Steel | |

| Travelling Speed: | <120m/min |

| Working Temperature: | -40℃~125℃ |

| Cable Load: | <120kg |

| Cable Loop Depth: | ≥0.3m (when travelling speed is no more than 35m/min) |

| ≤0.8m (when travelling speed is between 35-50m/min) | |

| ≥0.8m (when travelling speed is between 50-80m/min) |

Application

Festoon systems are commonly used in environments where overhead cranes, hoists, or other types of material handling equipment are required.

Industries such as manufacturing, warehouses, and ports often utilize festoon systems to facilitate the movement of materials and products.

Product Classification

Related Products

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.