Explosion Proof Rope Hoist

The explosion proof rope hoist is complied with ATEX Standard. It is widely used in various occasions that require explosion-proof measures, such as petroleum, petrochemical, oil depots, chemicals, coal mines and other environments with potential fire and explosion hazards. It can improve working conditions and increase labor productivity while ensuring.

Classification/Duty: M5

Heavy Duty Motor

Up to IIC IP65 / H Insulation

60%ED Rating

Over Heating Protection

Overloading Protection

Maintenance Free

Offshore Platforms (Oil & Gas), Oil Refineries, Chemical Plants, Waste Water Treatment, Paint Shops, Gas Power Plants, Printing

Description

Explosion Proof Rope Hoist is complied with ATEX Standard. It is mainly used in environments where there is an explosive mixture of flammable gas or steam and air. This equipment is made of special spark-free materials and has good explosion-proof performance, ensuring safe use in hazardous environments.

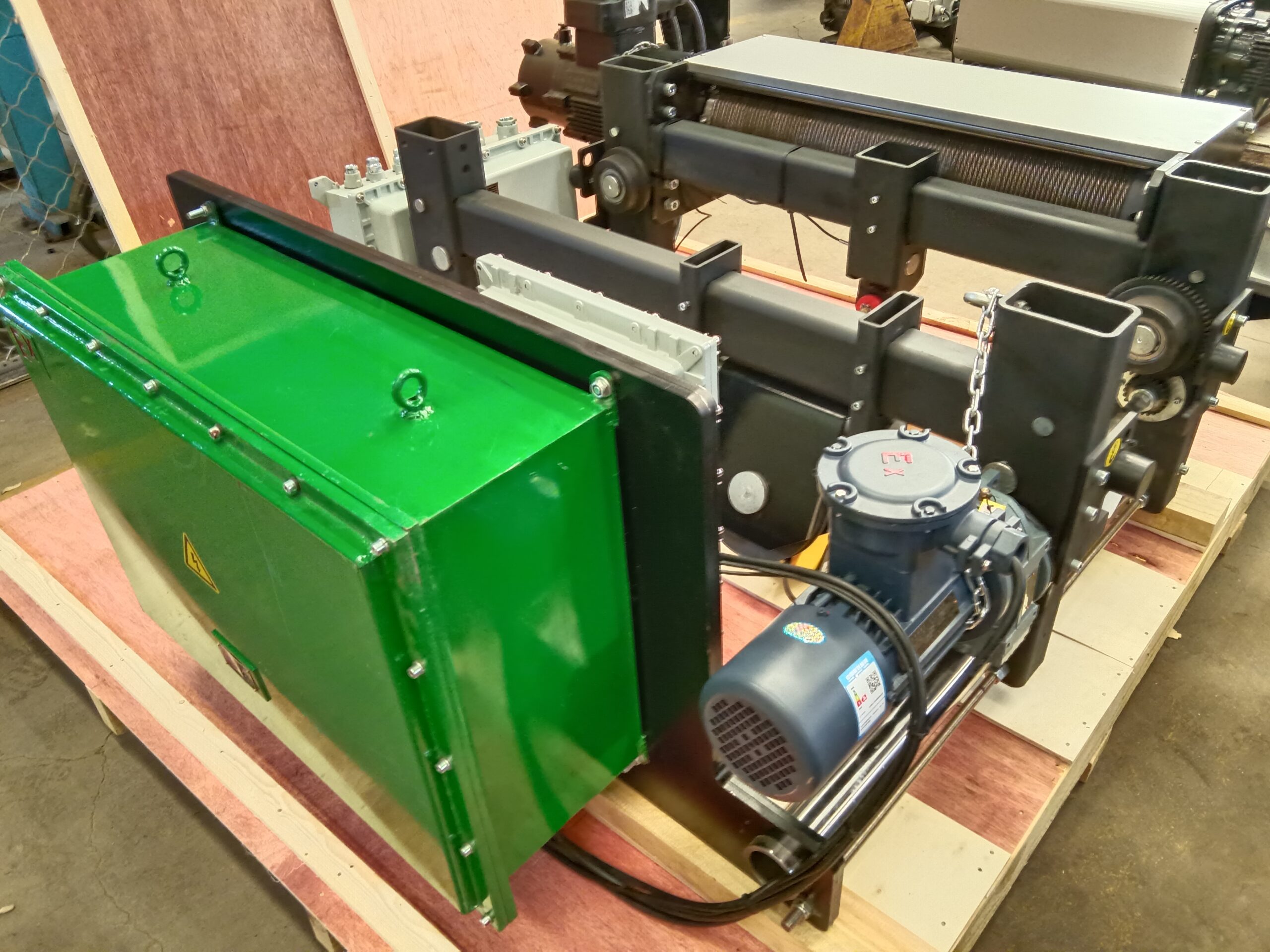

The explosion proof rope hoist is a “flameproof” special light lifting equipment, mainly composed of a motor, drum, wire rope, rope guide, hook, electric sports car and remote control. Its parts are made of special spark-proof explosion-proof materials, and the explosion-proof level reaches DIIBT4 and DIICT4, with good safety. Explosion proof rope hoist is suitable for explosive mixtures formed by specified flammable gases, steam and air in the factory, and is widely used in factories, mines, metallurgy, electricity, light industry, chemical industry, ships, railways, construction and other industries.

Technical Data

| Parameter | Specification |

|---|---|

| Maximum Load Capacity | Up to 80 tons |

| Motor Type | 3-IN-1 Explosion Proof Geared Motor |

| Protection Rating | IP65 |

| Insulation Rating | H |

| Overheating Protection | Yes |

| Overloading Protection | Yes |

| Maintenance Requirement | Maintenance Free |

| Track Type | C-profile Festoon System |

| Cable Type | Complete Rubber and Round Form Cable |

| Trolley Type | Nylon Trolley |

Features

Feature Description Spark-Proof Design Spark-proof measures for hazardous environments; bronze-coated hooks and nylon sheaves reduce spark risk. Ex-Protection Class Available in Ex-classes: dIIBT4, eIIBT4, IICT4, eIIIBT4. Duty Class Options M3, M4, and M5 for various operational needs. Power Supply System Ex-proof mobile supply with C-profile festoon system for flexibility. Durable Cable and Trolley Rubber and round-form cables; nylon trolley design minimizes friction. Limit Switches Dual-limit switches for safe bridge and trolley operations. Advanced Configurations Low headroom design, smart driving mechanism, 2-speed trolley, and dust-proof brakes. Adjustable Lifting Limit Switch Programmable four-step rotation for precise control.

Advantages

- Complied with ATEX standard.

- Classification: M5

- Optimized design in line with FEM standards.

- The overload protection function is usually set, 100% overload alarm, 110% overload can drop but not rise, 125% overload automatically stops.

- Equipped with an intelligent safe operation monitoring system, which can continuously record the working status and prevent non-professional operation.

- The controller will perform a self-check before starting, including the power supply voltage level, default phase, button zero state and the validity of each safety device.

- The three-point support statically determinate structure reduces internal stress, and the side-mounted reducer and cantilever motor form a flexible drive system to ensure stable operation and low noise.

- Imported motor, aluminum alloy wire drawing, good heat dissipation, overheating protection and alarm function.

- The whole machine is maintenance-free design, with few wearing parts and convenient maintenance.

Product Application

Explosion proof rope hoist are suitable for environments with explosive mixtures, such as environments with specified flammable gases or steam in factories. Its lifting speed is normal, which can meet the requirements of precision loading and unloading, sand boxes and molds, machine tool maintenance and other fine operations. In addition, explosion proof rope hoist is also suitable for non-mining working faces in Class I explosion-proof coal mines and Class II explosion-proof places with explosive gas mixtures composed of flammable gases or steam and air of levels ⅡA, ⅡB, and ⅡC, and temperature groups T1-T4. The working environment temperature is -25℃~40℃, which is suitable for indoor use; when used outdoors, protective devices are required.

SIMILAR PROJECT

Sinomac Industrial(SANOMAC) is a professional crane system and hoist system slolutions provider.