Energy Chain

Crane Parts Service

Material of Energy Chain is generally engineering plastic containing nylon PA6 material.

This material gives nylon energy chain the characteristics of high mechanical strength, wear resistance and good flexibility. In addition, nylon energy chain is flame retardant, low temperature resistant, antistatic, as well as good toughness and high elasticity. These characteristics enable nylon energy chain to maintain good performance in various working environments.

CNC Machine, Electronic Equipment, Glass Machinery, Injection Molding Machine Manipulators, Handling Machinery, Plastic Machinery, Lifting Equipment, Woodworking Machinery, Automobile Industry, Industrial Vehicles, Metal Processing Machines, Machine Tools, Casting Machinery, Port Equipment and Other Industries.

Download:

Movable Power Supply System

Description

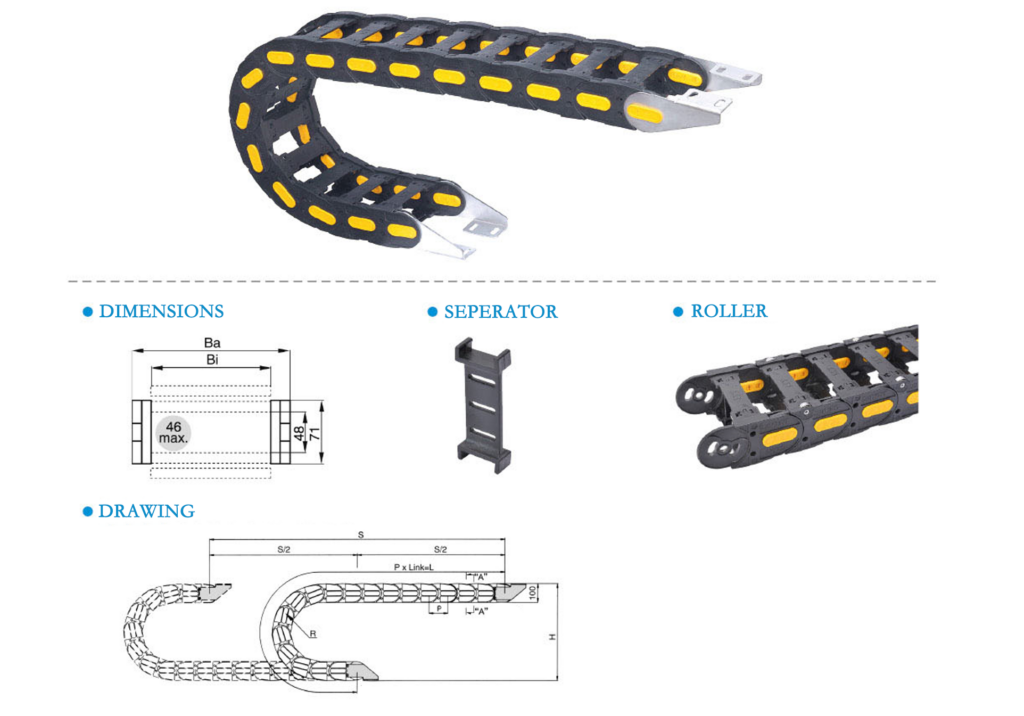

Energy chain is a protective track made of modified nylon injection molding. It looks like a tank chain and is mainly used to support and protect cables, oil pipes, air pipes, water pipes and other wire conduits. The energy chain consists of multiple interconnected energy chain sections, each of which can be flipped open for easy assembly, disassembly and maintenance. The unit chain links of the nylon energy chain are composed of left and right chain plates and upper and lower cover plates. This design makes the layout and protection of cables and other conduits more convenient.

The material of nylon energy chain is generally engineering plastic containing nylon PA6 material. This material gives nylon drag chain the characteristics of high mechanical strength, wear resistance and good flexibility. In addition, nylon drag chain is also flame retardant, low temperature resistant, antistatic, as well as good toughness and high elasticity. These characteristics enable nylon drag chain to maintain good performance in various working environments.

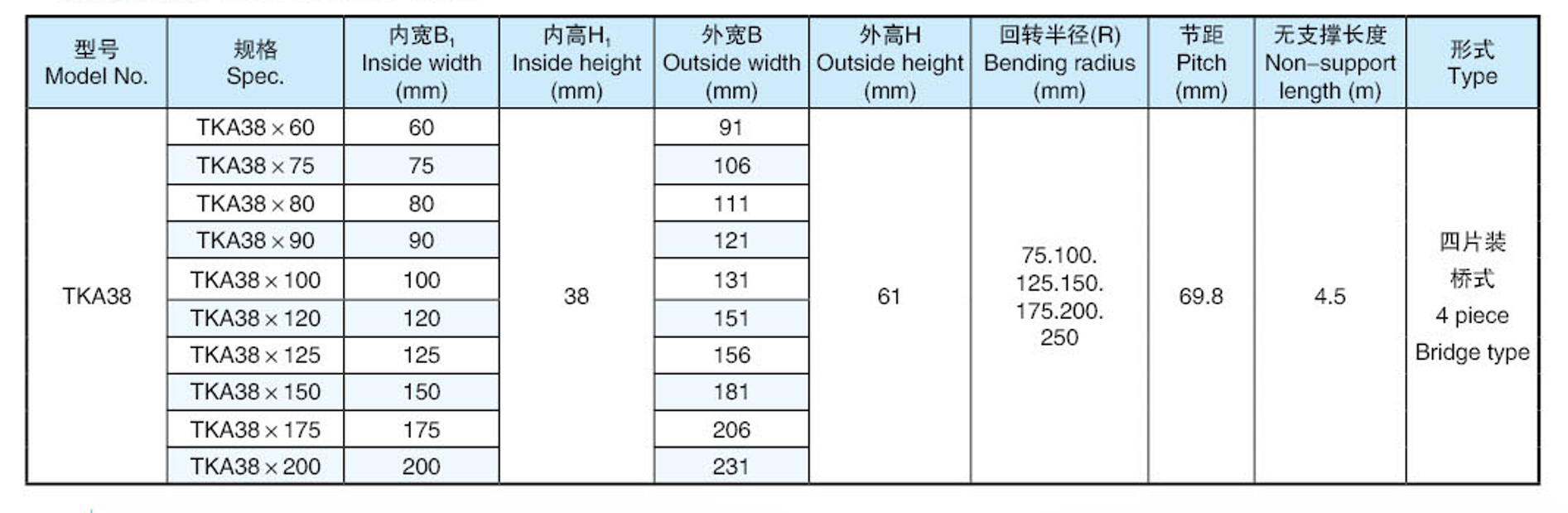

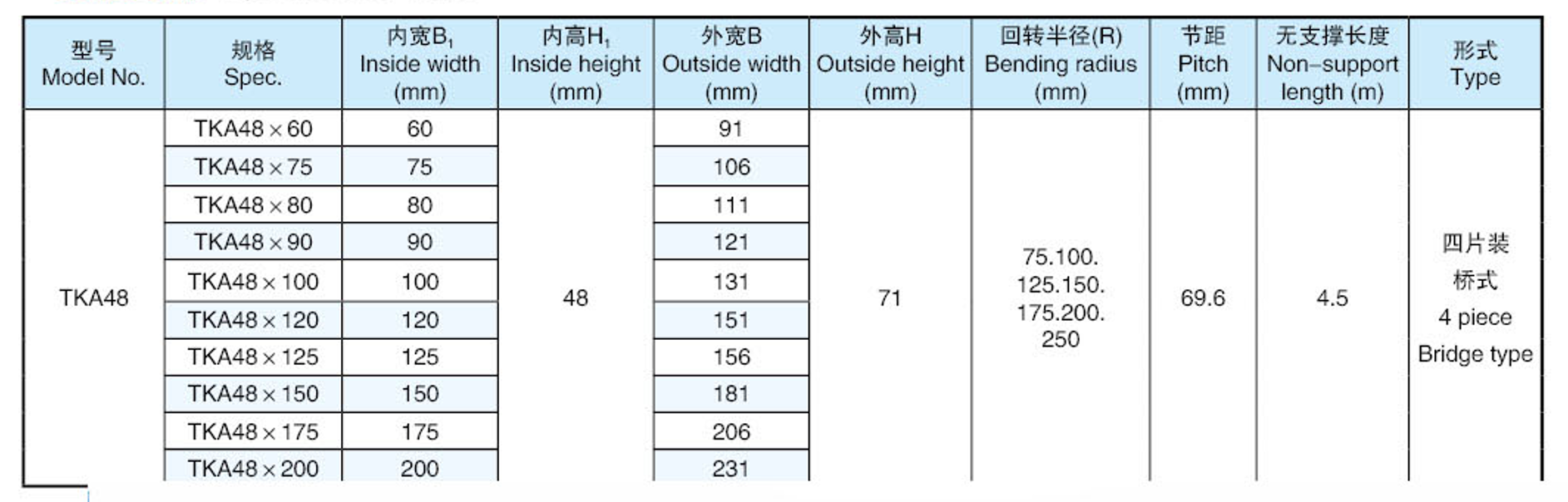

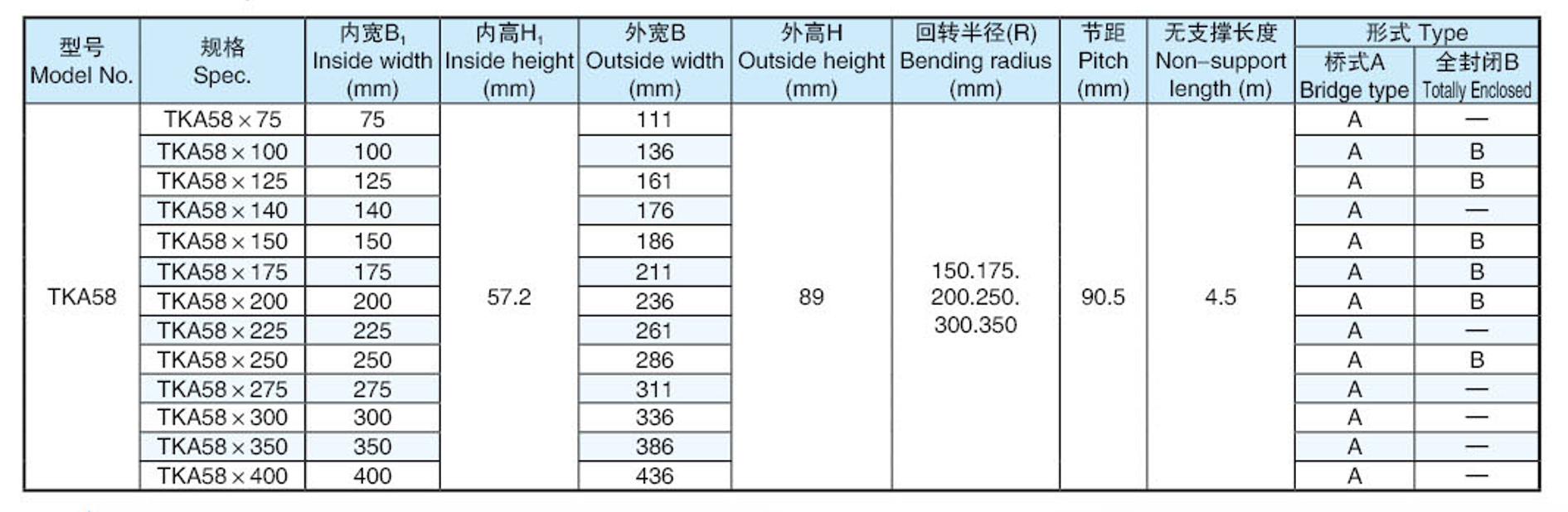

Technical Data

Selection

Selection Principles

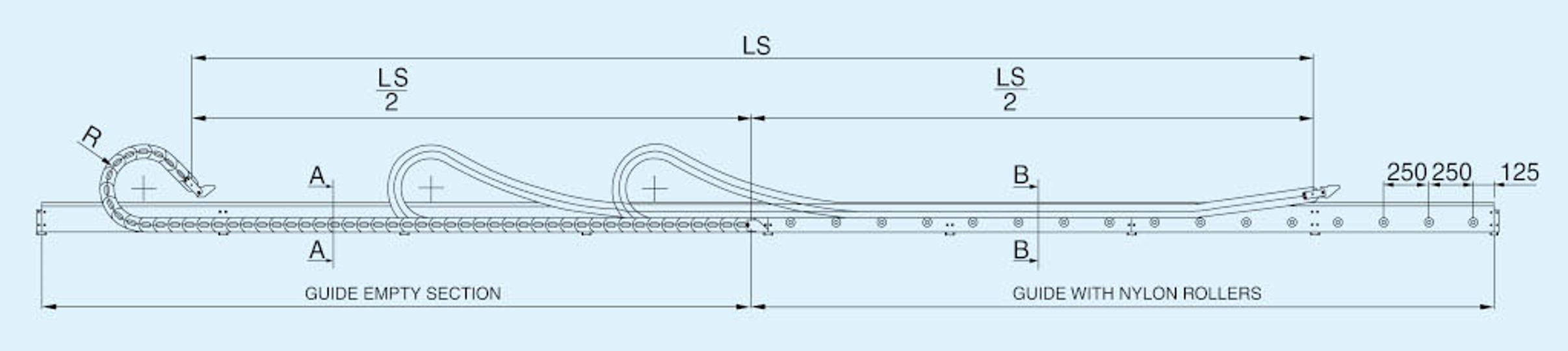

Inner height: Take the one having the largest outside diameter among the cable, oil pipe, gas pipe and/or water pipe that are to be internally laid plus at least 10% space margin as H, the inner height of the chain. When these items are to be mounted one on top of another, the piling height shall be used as a reference erection height.

Inner width: Use those electric cable, oil pipe, gas pipe and/or water pipe that have comparatively larger outside diameters, The sum of all diameters shall be regarded as the reference inner width of the chain. 10% space margin is required.

Bending radius: Select the one among the internally mounted electric cable, oil pipe, gas pipe and/or water pipe which are of the largest bending radius as are ference item. Over 10% space margin is required.

Considering Factors

1) Quantity, weight and dimensions of the electric wires and flexible hoses.

2) Travel distance

3) Limitations such as height and width for the installation.

4) Method of assembly and the fixed direction.

5) Travel speed.

6) Working environment

What mentioned above shall determine what/which series chain product shall be chosenand the number of partition plate and shall also determine other factors as follows:

- The total length of the drag chain and determine whether guide channel is required.

- The Bending Radius

- The Type of Connectors

- Which series of drag product to be used

- Whether open type or closed shall be used

Applications

Energy chain is normally used for the working conditions where reciprocating movement is required. lt can be used to haul the intemally-installed electric cables.oil pipes, gas pipes and water lines and protect them from damaging.

Each link of a chain is openable, which facilitates the installation and maintenance operations. When the chain is in operation, the following features can be obtained such as low level noise, friction resisting and high speed traveling.

The energy chain has been widely used in the digitally controlled machine tools.electronic equipment, lifting and transport devices, manipulators and automatic warehousing.

With advances in automation and increase in traveling speed and accelerated speed, more rigid and stricter management requirements are required in terms of energy control for the equipment and the moving parts of the system.

Based on the above, the basic and essential factors and characteristics of the best cable load system and its associated composite operating performance areas follows:

The Acent drag chain is made of reinforced nylon or aluminium-steel etc.

Thanks to its super quality and the best selection of material, Acent drag chain,which has been already widely used in different applications, offers excellent operating performance, low prices and lighter weight.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.

RELATED SOLUTION