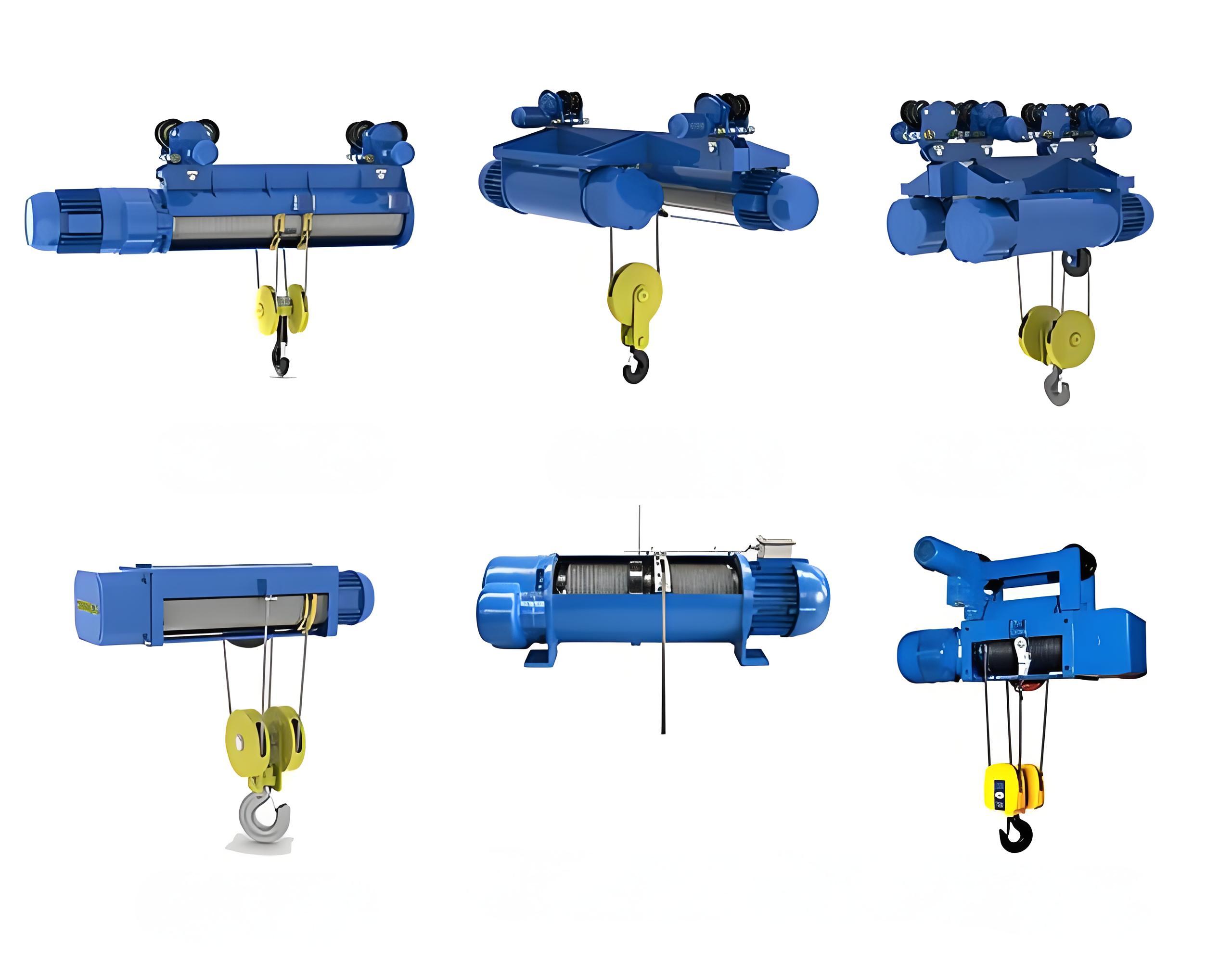

Electric Wire Rope Hoist

CD MD Electric Wire Rope Hoist

Electric Wire Rope Hoist is a small lifting equipment, which can be installed independently on I-beam, or it can be installed and used together with single-beam bridge crane, double-beam bridge crane, gantry crane and jib crane lifting equipment.

Product Type : CD MD

Lifting Capacity: 0.5~80t

Lifting Height: 6~50m

Lifting Speed: 0.8/8 m/ min or Customized

Working Class: M3, M4, M5, M6

Ambient Temperature: -25~60℃

Factories, mines, ports, cargo storage areas and shops, and is essential for improving work efficiency and improving working conditions.

Description

Electric Wire Rope Hoist mainly includes CD type, MD type and HC type wire rope electric hoist. Generally, the working speed of CD1 type electric wire rope hoist is single speed 8 m/min; the working speed of MD1 type electric wire rope hoist is double speed 0.8/8 m/min. The lifting capacity of CD1 and MD1 electric wire rope hoists is 0.25 to 16 tons. CD and MD wire rope electric hoist is a kind of light lifting equipment.

HC type wire rope electric hoist is a heavy lifting equipment. The working speed of HC type electric hoist is single speed, and the lifting capacity of hoist ranges from 16 tons to 80 tons.

In addition, the hoist is also can be used as the winch to pulling some materials.

Technical Data

| Model | 0.5T | 1T | 2T | 3T | 5T | 10T | ...T |

| Capacity(t) | 0.5 | 1 | 2 | 3 | 5 | 10 | ... |

| Standard lift(m) | 0-80 | 0-80 | 0-80 | 0-80 | 0-80 | 0-80 | ... |

| Lifting speed(m/min) | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | 7/0.7 | ... |

| Running speed(m/min) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | ... |

| Wire rope type | 6×37-4.8-180 | 6×37-7.4-180 | 6×37-11-155 | 6×37-13-170 | 6×37-15-200 | 6×37-17.5-200 | ... |

| I Beam track type | 16-28b | 16-28b | 20a-32c | 20a-32c | 25a-63c | 28a-63c | ... |

| Motor power/kw | 0.8 | 1.5 | 3.0 | 4.5 | 7.5 | 13 | ... |

| Motor R.P.M(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | ... |

| Voltage(V) | 220-460 | 220-460 | 220-460 | 220-460 | 220-460 | 220-460 | ... |

| Frequency(Hz) | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | ... |

| Phase | 3 | 3 | 3 | 3 | 3 | 3 | ... |

Features

Electric Wire Rope Hoist is a small lifting equipment that can be installed on a single girder bridge crane. Gantry cranes can meet normal applications only as a normal speed. It is widely used in factories, mines, ports, cargo storage areas and shops, and is essential for improving work efficiency and improving working conditions.

- Reducer

It adopts a three-stage locking motor gear transmission structure; the gears and gear shafts are made of alloy steel after heat treatment, and the shell and cover are made of high-quality cast iron, with accurate assembly and good sealing. The reducer operates independently for easy loading and unloading.

- Control Box

It has a protection device for up and down trip circuit breakers, which can cut off the main circuit in an emergency to ensure the safe operation of the electrical block, long service life, and safe operation of electrical components.

- Wire Rope

Adopted the galvanized steel wire rope, long service life.

- Motor

The hoisting motor adopt Top 1 industrial Brand squirrel cage motor with a large starting torque to brake the induction motor. No additional lightning arrester is needed. The load continuity factor of the motor is 25%; Insulation:F/H, and the protection level is isIP44 / IP54 .

- Push Button Switch

Adopted the Industrial famous brand, which is broken-resistant. Protection Class is up to IP65

- Gear

It adopts Japanese technology, innovatively adopts high-speed synchronous gear symmetrical arrangement, and adopts international standard gear steel. Compared with ordinary gears, it is more wear-resistant, more stable and labor-saving.

- Hook

It is made of high-strength, high-safety high-quality alloy steel; with a new design, the weight will never be lost.

Advantages

1. The trolley installation should be adjusted according to the width of the I-beam track with washers to ensure that the clearance between the wheel edge and the track is 4-5mm;

2. Installation, wiring and commissioning of the lifting weight limiter;

3. Installation and commissioning of the limiter (the limit is adjusted upward, the top of the hook and the drum shell are kept about 200mm space, when the limit is lower, the remaining total safety wire rope on the drum is kept at least 2 laps);

4. Check the refueling amount and oil quality of the reducer;

5. Inspection and adjustment of electronic brake;

6. Check and ensure the wiring inside the control box is firm, ensure the insulation resistance is normal, and ensure the cable wiring from the control box is correct;

7. Check and make sure the wedge and wedge sleeve are installed firmly;

8. Check and make sure the wire rope is normal, to avoid bending, corrosion, broken wire;

9. No-load test run and load test run.

Product Application

Product Classification

Related Products

SIMILAR PROJECT

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.