Electric Telescopic Spreader

APPLICATION: RTG Cranes, RMG Cranes, Shore to Shore Cranes, Portal Gantry Cranes

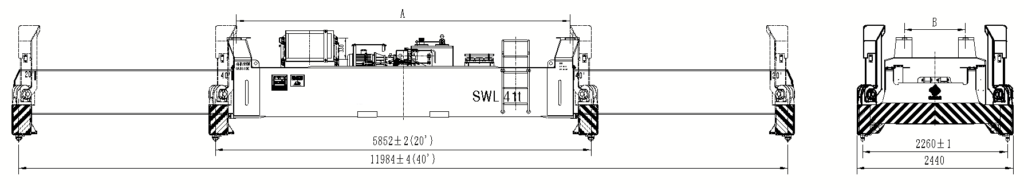

ISO CONTAINER SIZES: ISO Standard 20’, 40’ and 45’ containers

SPREADER CONTROL: Mechanical

OPTIONS: Rotating Spreaders, ±1200 Movement Spreaders

CE CERTIFICATION: Include

Description

Electric telescopic spreader is the most commonly used type for container-dedicated cranes. It automatically adjusts its length to handle lifting operations for containers of different sizes. The telescopic and lock/unlock actions of the electric single-container telescopic spreader are motor-driven, suitable for ISO standard 20ft, 40ft, and 45ft containers. Telescopic container spreader is used for handling ISO containers up to 65 tons deadweight.

Electric telescopic spreader is the most commonly used type for container-dedicated cranes. It automatically adjusts its length to handle lifting operations for containers of different sizes. The telescopic and lock/unlock actions of the electric single-container telescopic spreader are motor-driven, suitable for ISO standard 20ft, 40ft, and 45ft containers. Telescopic container spreader is used for handling ISO containers up to 65 tons deadweight.

Telescopic spreader also features fast and smooth movement, flexible operation, high safety, and rich functions. For example, in order to improve work efficiency and adapt to the lifting requirements of different cranes, various mechanisms can be added to the telescopic spreader, such as automatic guides, deflection devices, rotation mechanisms, and center of gravity adjustment mechanisms, making the telescopic spreader more functional and diverse.

The design of the electric telescopic spreader takes into account factors such as safety, stable performance, and operating efficiency. It is made of high-quality high-strength steel welding. Compared with other spreaders made of ordinary steel, it is lighter and consumes less energy.

At the same time, telescopic container spreader can automatically switch between 20 feet and 40 feet in no more than 30 seconds, which greatly improves operating efficiency.

Technical Data

| Model | ESS040ft | ESS040ft_ RSH _ER360 | ESS040ft_RHH _ER360_CT+1200FF4 |

| Weight | 7.3 tons | 9.5 tons | 13 tons |

| Swivel Type | ISO floating swivel, driven by deceleration motor | ||

| Extension Type | Motor-driven, connected by roller chain | ||

| Rotation Angle | 360℃(optional) | ||

| Translation Distance | / | / | ±1200mm |

| Rotation Type | / | Motor-driven, rotation supported by rotary bearing | |

| Guide Mechanism | Detachable fixed guide plate (FF, optional) | ||

| Power Supply Voltage/Frequency | AC 380(3P)/50Hz | ||

| Total Power | ≤6KW | ≤8KW | ≤14KW |

| Allowable Eccentric Load | ±10% | ||

| Rated Load | ≤41 tons | ||

| Rated Load of Lifting Ear | 4×10.5 tons | ||

| Ambient Temperature | -20℃ to +60℃ | ||

| Locking Time | ~1s | ||

| Extension Time (20ft~40ft) | ~22s | ||

| Rotation Speed | / | 1r/min | |

| Translation Time | / | / | ~35s (optional) |

| Translation Type | / | / | Motor-driven, connected by roller chain |

| Protection Level | IP55 | ||

| Control Voltage | AC 220V (optional) | ||

| Maximum Power Consumption | 4KW | ||

Feature

- Motorized Operations:

- All operations of the container lifting spreader are driven by electric motors.

- The electric motor is selectively powered only during necessary actions, ensuring minimal power consumption during idle periods.

- Advantages over Hydraulic Spreader for container lifting:

- Compact structure and lightweight design.

- Environmentally friendly with lower energy consumption (around 10% of hydraulic spreader).

- Reduced running costs, fewer faults, and easy maintenance.

- Low noise and no oil leakage, contributing to a green and clean working environment.

- Fixed Guide Plate Design:

- Utilizes a fixed guide plate to assist drivers in precise container handling.

- Enhanced structural strength compared to movable guide plate devices.

- Significant cost reduction in comparison.

- Electrical System:

- Installation of an advanced electrical system on the spreader.

- Components include an electrical control box, limit switches, junction box, modules, indicators, plugs, various sensors, and signal transmitters.

- Controls and provides feedback for all container lifting spreader actions.

- Optional Accessories for Maintenance and Safety:

- Customizable with optional accessories based on maintenance, safety, and protection requirements.

- Available accessories include ladders, guardrails, anti-fall lugs, anti-drop chains, and self-closing doors.

- Provides flexibility to meet specific operational and safety needs.

Project Case

Sinomac Industrial(SANOMAC) lifting equipment is operational in over 90 terminals across 25 countries worldwide. With a strong presence on both the East and West Coasts of the United States, as well as in major European, South American, African, Oceanic, and Asian ports, Sinomac Industrial(SANOMAC) reliable and efficient spreaders are widely embraced globally.

Experience the superior efficiency and eco-friendly performance of Sinomac Industrial(SANOMAC) telescopic spreader, Upgrade to a cutting-edge solution that combines the power of electric motor-driven operations, cost-effectiveness, and advanced safety features. Elevate your lifting experience with Sinomac Industrial(SANOMAC) – where innovation meets reliability.

Contact us today to learn more about our electric telescopic spreader and explore how Sinomac Industrial(SANOMAC) can enhance your material handling capabilities. Elevate your operations, choose Sinomac Industrial(SANOMAC) – Empowering Your Lift, Elevating Your Success.

Product Classification

Related Products

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.