Double Girder Overhead Shop Crane

Overhead crane series

Capacity: 5~800t

Lift Height: Max. 160m

Span: 5~50m or Customized

Work Duty: M3~M8

Protection class: IP54, IP65

Working temperature: -40~+40℃

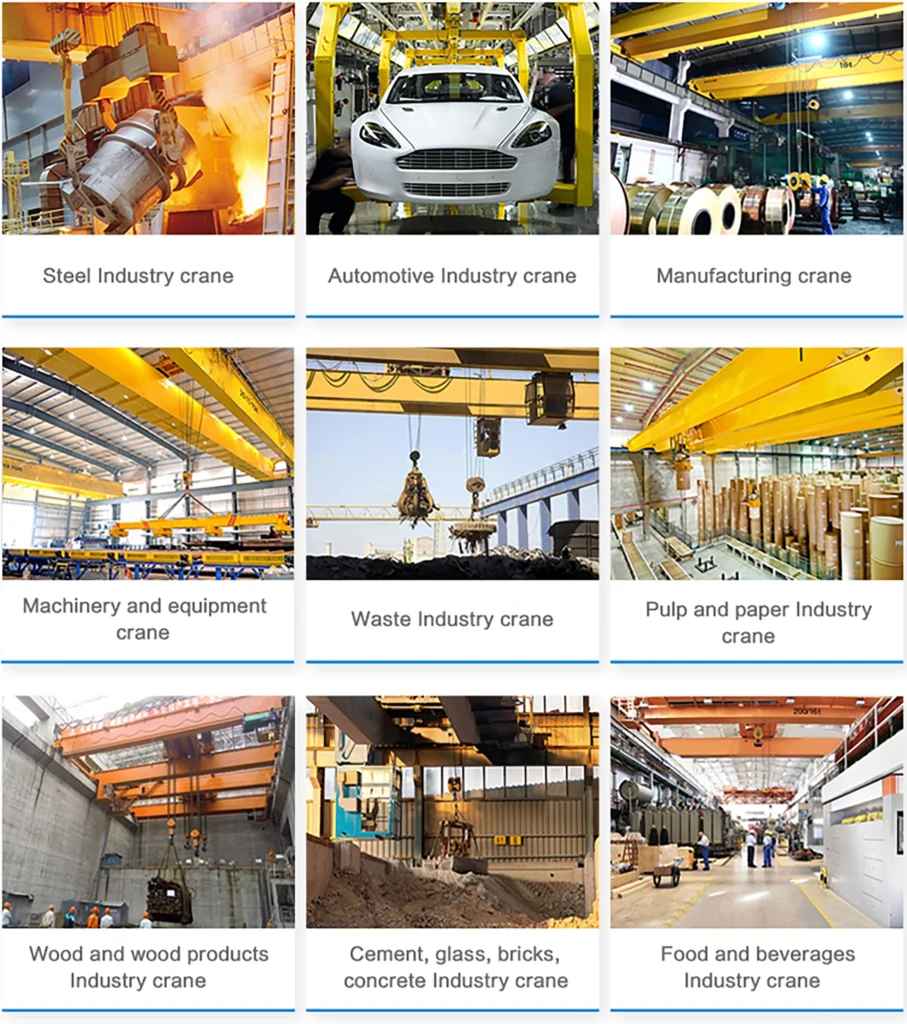

Widely used in indoor and outdoor industrial and mining enterprises, iron and steel chemical industry, railway transportation, port and wharf, logistics and other places

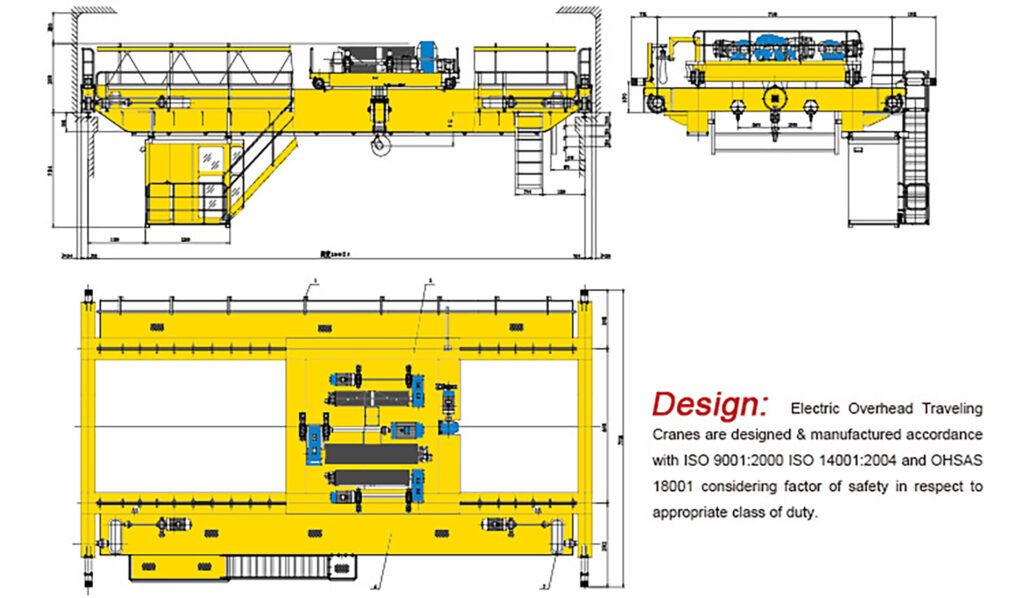

Description

Double Girder Overhead Shop Crane adopts a lightweight design concept, optimize the crane structure to reduce the weight of the product, use high-performance components to reduce the overall size, use an integrated transmission mechanism to reduce transmission links, use overall processing to simplify the production process, and use intelligent control to make it easy to operate. In view Overhead Shop Crane is equiped the open winch trolley, so it’s also called open winch overhead shop crane.

Overhead Shop Crane adopt a modular design, and make parts with similar functions into interchangeable standard modules with multiple uses and interconnections. Through different combinations of modules, a series of products with multiple specifications are formed.

By rationally planning the main parameters, structural forms, and functional characteristics of this series of cranes, adop the open winch trolley, it has good scalability, so that a variety of series of lifting products can be produced to meet the different technological needs of users.

According to user needs, this series of Overhead Shop Crane can be equipped with intelligent modules, which can realize unmanned automatic operation; and the crane control system can be connected to the factory management system to realize the automated production management of the entire factory.

Product Details

Features

MAIN GIRDER

- FEM/DIN Standard Design.

- Raw Material from Famous Steel Mills.

- CNC Cutting for Complete Cover Plate, Web Plate & Rib Plate, High Deflection Accuracy.

- High Quality Automatic Welding and NDT Inspection.

- Shot-blasting Sa2.5 to make sure the paint adhesion.

- The Main Girder with High Temperature Resistance can be working under the temperature up to 40℃

- Larger Span Main Girder (Over 12M) can be designed into high strength bolts connection with positioning hole, which can lower the shipment cost and easy to assemble the main girder.

- Thickness of Paint ≥ 120 μm.

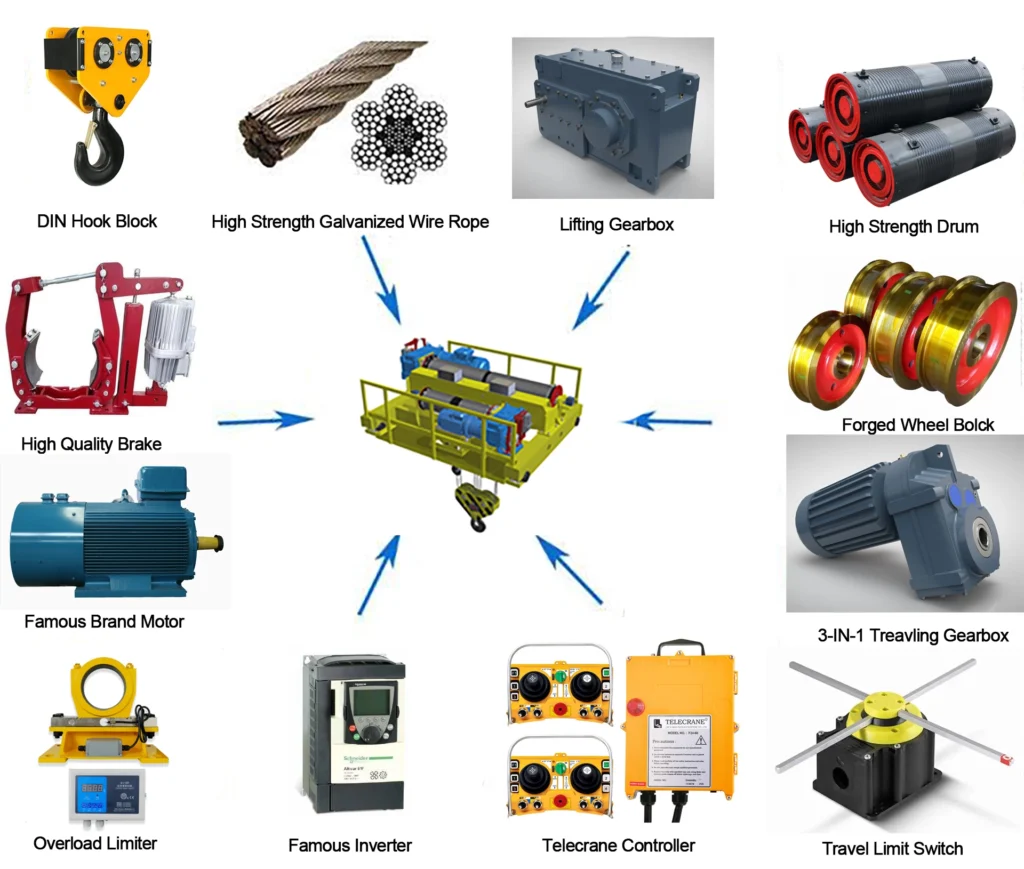

ELECTRIC TROLLEY

- FEM/DIN Standard Design

- Adopted Planetary Gearbox with ABB Motor, Lowest Noises, Free Maintenance, Free Lubricant Oil Fill, Lower Headroom.

- Full Inverter (VFD) Drive. Inverter adopted Schneider Inverter Company

- Galvanized Steel Rope adopted the crane industrial famous brand. High Strength 2160N/m2 with long Service Life and 1.8 times safety factor.

- The Hook Block adopted the forged hook, Material of hook: 35CrMo.

- The Brake Type- Electromagnetic inserted into the motor which have the automatic brake, if the power is fault.

- Hoist has the up/down limiter, cross travel limiter and overload limiter to make sure the safety.

- The Duty/Classification is up to FEM 4M/ISOM7.

END CARRIAGES

- Wheel is made of forged 42CrMo alloy steel, which is overall quenching and tempering treatment with wear resistance and high hardness advantages.

- Wheel bearings adopt self-aligning tapered roller bearings, which can automatically adjust the level of the crane.

- The drive adopts a 3-IN-1 SEW/ABB GEARED MOTOR, which is completely sealed compact gearbox with free of maintenance for life. the geared motor and the end carriages are assembled with a torque arm, which has the advantages of high transmission efficiency and low noise.

- The motor reducer adopts a SEW variable frequency motor, with protection grade IP55, F class insulation, stepless speed regulation, hard tooth surface, quiet design, good sealing, and stable operation.

ELECTRIC PANEL

- The electric cabin protection class can be up to IP67.

- All the Main Electric Component is adopted Schneider.

- All wires have color, number, or wire size marks, which can be easy identified.

- All the movement is controlled by Inverter (VFD), the Inverter is adopted the SCHNEIDER Brand.

- Cross Travel is adopted festoon type power system with galvanized sliding rail and cable trolley.

- All the same bay cranes will be equipped the infrared anti-collision limit switch.

- Equipped sound and light alarm system, Emergency stop, lower voltage protection, phases failure protection, Phase lose protection, voltage fluctuation Protection system and current overload protection.

Advantages

- Compact and reasonable structure, beautiful appearance

- Stronger carrying capacity, more efficient material handling and longer service life

- Excellent and strong performance, suitable for a variety of harsh working environment

- Strictly control the production and inspection process to ensure product quality

- Intimate technical guidance and after-sales service

Application

Electric double girder overhead shop crane is an important tool and equipment to realize the mechanization and automation of the production process in modern industrial production and lifting transportation.So the double girder overhead shop crane has been widely used in indoor and outdoor industrial and mining enterprises, iron and steel chemical industry, railway transportation, port and wharf, logistics and other departments and places.

Product Classification

Related Products

SIMILAR PROJECT CASES

Kinocranes is a professional crane manufacturer. We integrate crane research and development, manufacturing, sales, installation and service.