Double Girder Gantry Crane

Capacity: 0.5~800t

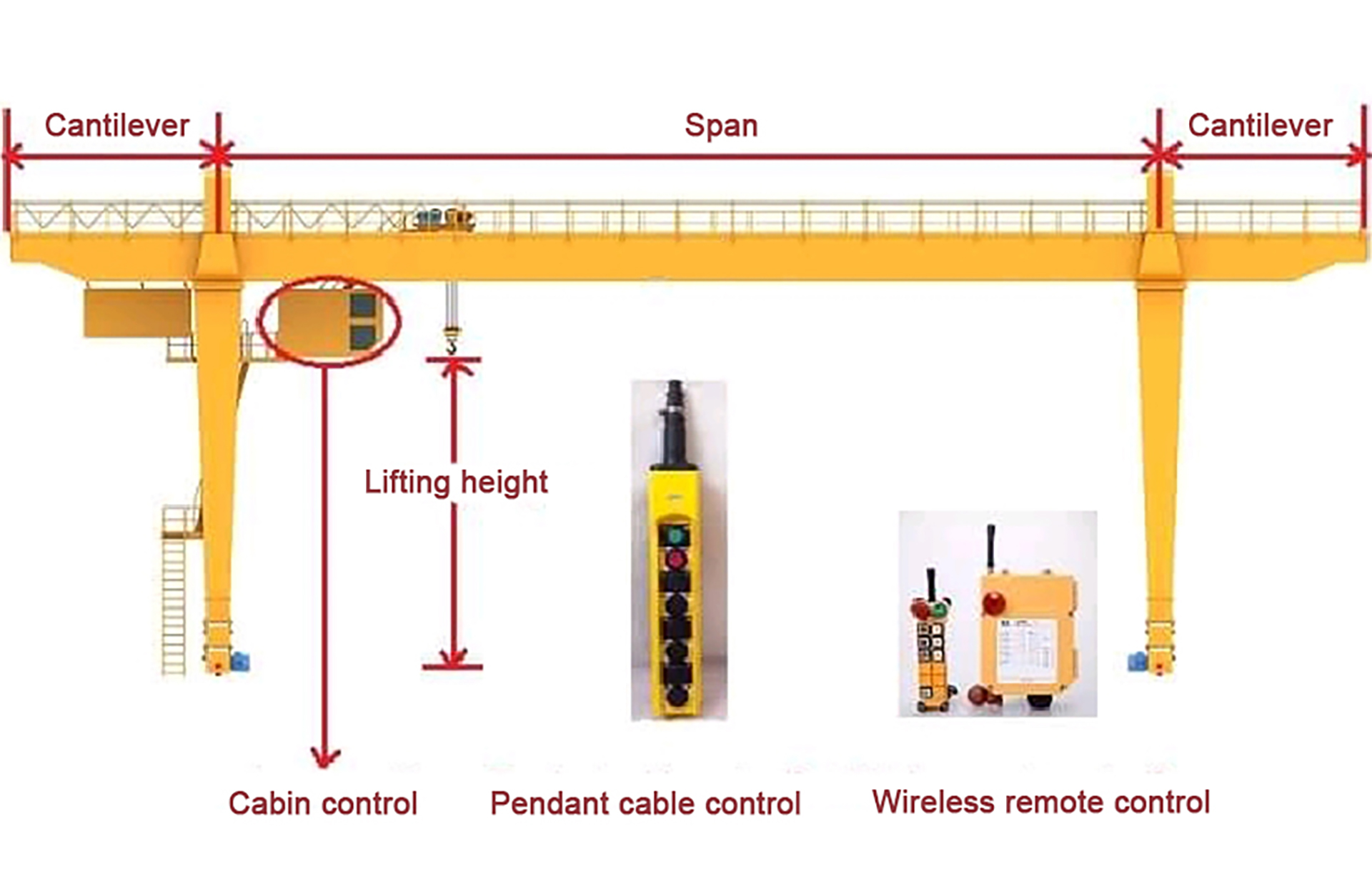

Span: 12~50m or Customized

Left/Right Cantilever: 1/3 of Span

Classification/Duty: A3-A8

Lifting Height: 3~80m/Customized

Lifting Speed: 2~16m/min/Customized

Cross Speed: 20~60m/min/Customized

Control Type: Pendant/Remote/Cab

Power Supply: 3PH 220V-480V/Customized

Description

Double girder gantry crane is composed of bridge frame, long traveling mechanism, trolley, winch and electrical equipment, etc.The bridge adopts box-type double-beam welding structure, and the operation mechanism of the trolley is driven separately, and all the mechanisms are operated in the driver’s cab.

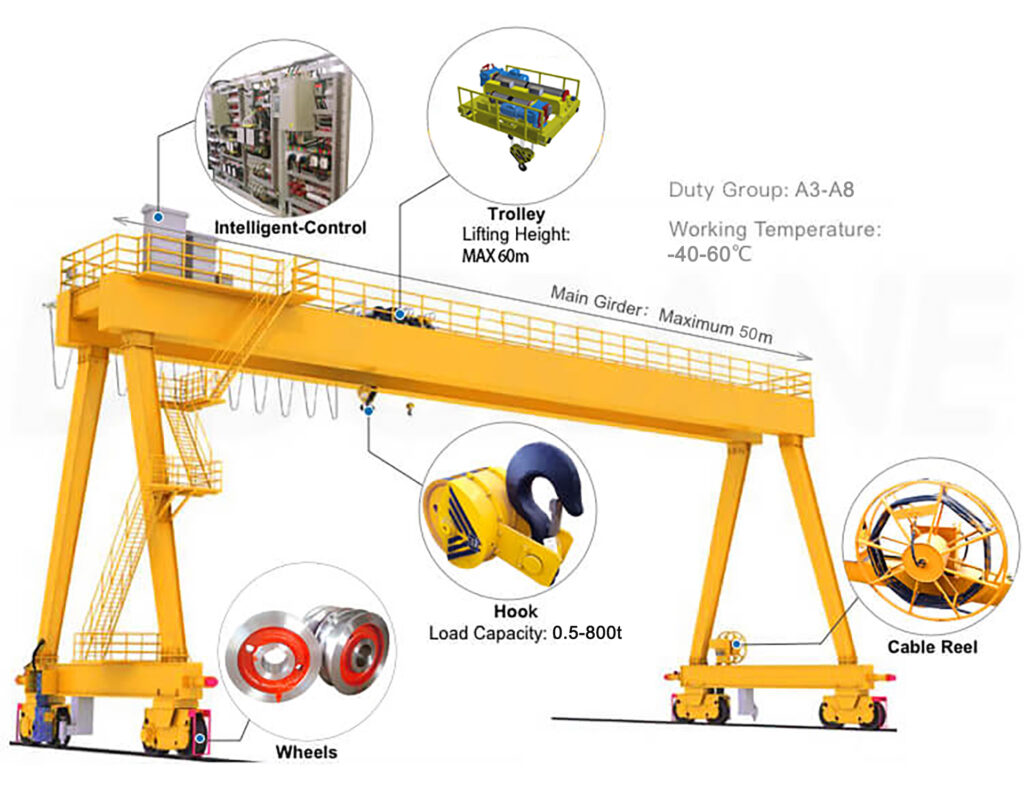

Double Girder Gantry Crane Main Component

- Main Girder

- Flexible Leg

- Ground Beam

- Rigid Leg

- Lifting Trolley

- Heavy Duty Trolley Festoon System

- High-strength Alloy Forged Hook

- LT Wheel Mechanism

- LT Power Supply Cable Reel Drum

- Maintenance Platform

This setup enables efficient and secure heavy load lifting and movement, making the double girder gantry crane a reliable solution for various industrial applications.

Double girder gantry crane is suitable for open warehouse, yard, railway freight station, port dock cargo area, such as loading and unloading and lifting.Can also be matched with a variety of spreaders for some special work.

Design

- Double Girder Gantry Crane Systems are designed in accordance with ISO, FEM and DIN standard.

- In double girder gantry crane, mechanism selections are made in accordance with the desired lifting and running speeds and working class.

- The use of box-shaped double beam welding structure, increase the working space and easy to transport, installation and maintenance.

- The car adopts the opposite rail cable conductive device.

- Standardization, serialization and generalization of parts and components.

- There are two kinds of cable coil type (divided into left and right end) and sliding line type (divided into left and right end) for users to choose.

- The driver’s cab has a wide field of vision and a linkage console, which makes the operation flexible, balanced and comfortable.It can also be equipped with fan, hot air device, air cooler, air conditioner, walkie-talkie, etc.

Advantages

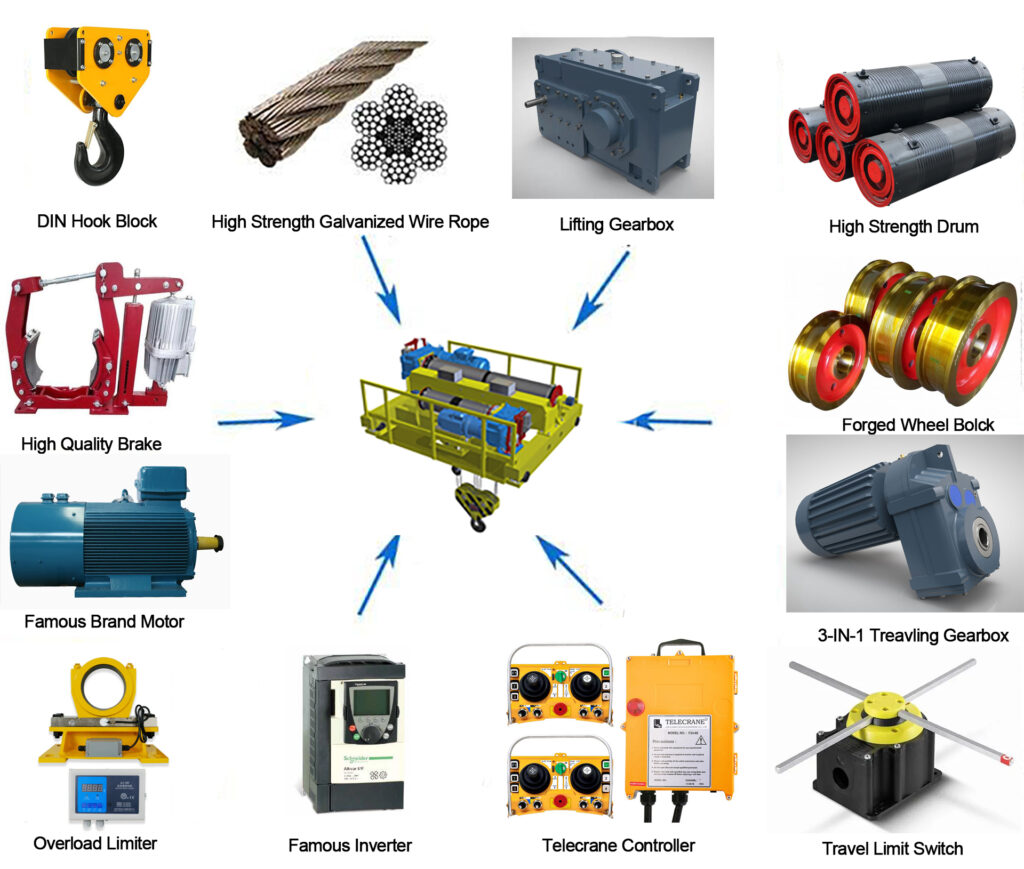

- Steel structure: Q235B/Q345B carbon structural steel with seamless once forming technology more strong and elegant. Suitable for different operation temperature;

- Lifting mechanism: Reducer, drum, motors protection class F class, China or World top quality motor brands, such as Jiamusi, SEW, ABM, etc;

- Hook: Finest steel forged hook, long using life;

- Wheels: Vacuum casting, with compact structure, convenient maintenance, high transmission efficiency and long service life;

- Travel mechanism: With China or world famous crane motor, reducer supplier, such as ABB, SEW etc;

- Electrics: ABB, Schneider or Siemens etc.

Technical Specifications

| Loading Capacity | 0.5~800t |

| Lifting Height | 3~80m or customized |

| Lifting Speed | Single speed: 2~30 m/min or customized |

| Variable speed: 2-30 m/min or customized | |

| Span | 3~50m |

| Left Cantilever | 1/3 of Span |

| Right Cantilever | 1/3 of Span |

| Lifting Mechanism | Winch |

| Work Duty | A3~A8 |

| Power Supply | AC-3Phase-220/230/380/400/415/440V-50/60Hz |

| Control Method | Ground handle control(Push button), wireless remote control, cabinet control |

| Application Area | Factory,workshop,warehouse,power station,logistic,etc. |

| Color | Customized |

| Working Temperature | -40~60℃ |

| Protection Class | IP54; IP55; IP65 |

Technology

- Variable Frequency Drives (VFDs): Enables smooth acceleration and deceleration, reducing wear and tear on components while optimizing energy consumption.

- Remote Control and Automation: Allows operators to control the crane remotely, enhancing safety and enabling more efficient operation.

- Load Sensing and Anti-Sway Systems: Employ sensors and algorithms to prevent load swinging, improving load stability and operator control.

- Collision Avoidance Systems: Integrates sensors and software to detect obstacles and prevent collisions during crane movement.

- Energy-Efficient Components: Utilizes energy-efficient motors and components to reduce power consumption and operating costs.

- Integrated Diagnostics and Maintenance Monitoring: Offers real-time monitoring and diagnostics to predict maintenance needs and minimize downtime.

- Wireless Communication: Uses wireless technology for data transmission between components, enhancing flexibility and reducing cable clutter.

- Advanced Safety Features: Includes redundant safety mechanisms, emergency stop systems, and overload protection to ensure safe operations.

- High-strength Materials and Manufacturing: Incorporates advanced materials and manufacturing techniques to enhance structural integrity and longevity.

Free support & Service

- Main girder fabrication drawing for site making

- Professional online technical support

- Free components supply in warranty period

If you need further assistance, guidance, or have any more questions for the double girder gantry crane, feel free to contact us.

SIMILAR PROJECT

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.