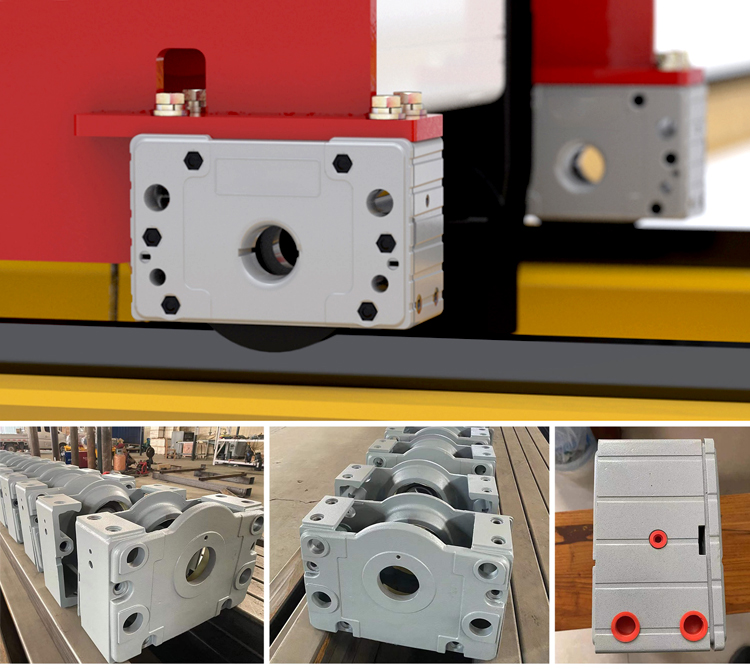

DIN Crane Wheel Block

Crane Parts Service

Material: 42CrMo/GGG 70/PA/PU or Customized

Hardness: 330HRC-400HRC (H&T)

Composition: Wheel, Shaft, Bearings and Bearing Housing, etc.

Wheel Diameter:Φ80, Φ112, Φ125, Φ160, Φ200, Φ400, Φ250, Φ315, Φ400, Φ500.

Crane Wheel is suitable for various engineering machinery fields, such as Overhead Crane and Gantry Crane. It has the characteristics of high strength, wear resistance, low noise, etc. Adopts modular design, is easy to disassemble and repair, and can carry a large weight range from 2.75 tons to 80 tons.

Description

Crane Wheel is mainly reflected in its high-precision positioning, high-efficiency operation and high load-bearing capacity. Through the integrated advanced control system and sensor technology, the crane wheel block can achieve high-precision positioning and navigation, ensure the precise movement of the stacker in the warehouse, reduce errors, and improve the accuracy of storage and picking operations .

In addition, the crane wheel block adopts optimized materials and structures to reduce friction and energy consumption and improve operating efficiency. Its high-strength load-bearing structure can withstand the weight of the stacker and cargo, ensuring stability and safety under heavy-load operations.

Crane wheel block is suitable for various engineering machinery fields, such as bridge and gantry cranes. It has the characteristics of high strength, wear resistance, low noise, etc. It adopts modular design, is easy to disassemble and repair, and can carry a large weight range from 2.75 tons to 80 tons . This design enables the travel wheel block to provide stable and efficient power transmission to meet the needs of different working conditions .

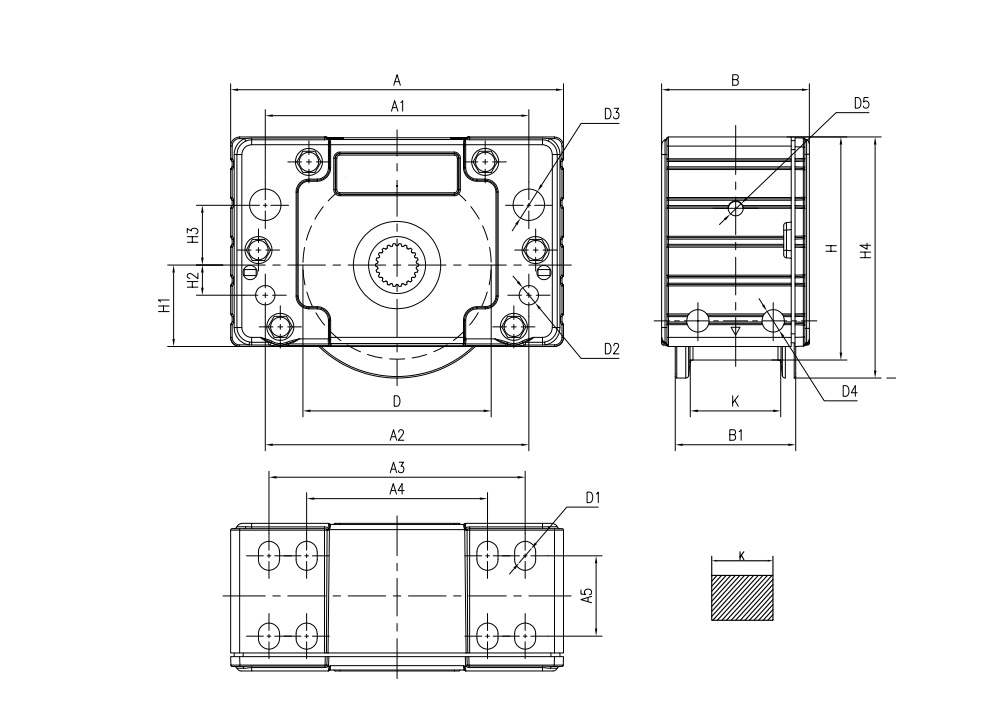

Technical Data

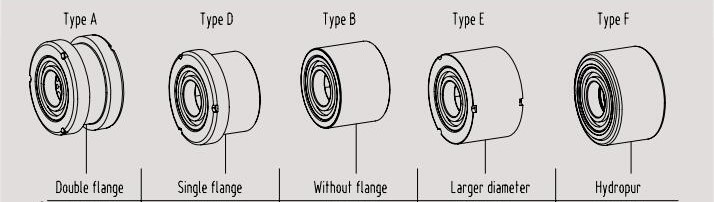

A: Double Flange – guided by rims on both sides, suitable for rail systems.

D: Single Flange – wheel guided by rim on one side, suitable for ground-based devices.

B: Without Flange – optional with side guide wheels or concave to meet customer specifications.

E: Enlarged wheel – larger diameter rimless wheel, suitable for applications with high ground clearance.

F: Without Flange Rubber Coated Wheel – rimless wheel in polyurethane with extremely high acceleration and quiet operation.

Technical Specifications

Typed | HWS80 | HWS112 | HWS125 | HWS160 | HWS200 | HWS250 | HWS315 | HWS400 | HWS500 |

A(mm) | 140 | 190 | 220 | 275 | 340 | 385 | 470 | 580 | 700 |

B(mm) | 74 | 96 | 98 | 110 | 130 | 150 | 180 | 210 | 240 |

H(mm) | 95 | 131 | 147.5 | 187 | 238 | 281 | 349.5 | 440 | 566 |

K(mm) | 40 | 55 | 55 | 60 | 60 | 75 | 90 | 100 | 100 |

H1(mm) | 36 | 47 | 53.5 | 70 | 90 | 89 | 114 | 144 | 183 |

H2(mm) | 25 | 30 | 20 | 25 | 35 | 50 | 70 | 95 | 110 |

H3(mm) | 30 | 40 | 40 | 55 | 75 | 80 | 80 | 130 | 160 |

H4(mm) | 103 | 141 | 160 | 200 | 254 | 293 | 367 | 460 | 589 |

B1(mm) | 60 | 80 | 80 | 89 | 101 | 110 | 130 | 158 | 170 |

A1(mm) | 110 | 145 | 175 | 220 | 275 | 310 | 370 | 450 | 580 |

A2(mm) | 110 | 145 | 175 | 220 | 275 | 310 | 370 | 450 | 580 |

A3(mm) | 110 | 145 | 170 | 220 | 275 | 290 | 360 | 440 | 620 |

A4(mm) | _ | _ | _ | _ | _ | 140 | 180 | 210 | 480 |

A5(mm) | 31 | 45 | 55 | 55 | 65 | 80 | 100 | 120 | 125 |

D(mm) | 4*M12 | 4*M12 | 4*M12 | 4*M16 | 4*M16 | 8*M160 | 8*M16 | 8*M20 | 8*M20 |

D2(mm) | 9 | 10.5 | 13 | 17 | 20 | 34F8 | 40F8 | 31H13 | 31H13 |

D3(mm) | 15 | 18.5 | 21 | 30 | 35 | 40 | 50 | 65 | 70 |

D4 | 4*M12 | 4*M12 | 4*M12 | 4*M16 | _ | 2*M12 | 2*M12 | 2*M12 | 2*M12 |

D5 | 2*M12 | 2*M12 | 2*M12 | 2*M12 | 2*M12 | _ | 2*M20 | 2*M20 | 2*M20 |

Weight KG | 4 | 10 | 15 | 26 | 41 | 70 | 220 | 220 | 380 |

Max.Load KN | 15 | 27.5 | 50 | 70 | 100 | 160 | 300 | 380 | 400 |

- Load Capacity

The design fully considers the load requirements of the stacker, and it can usually carry a large load to ensure the stability of the stacker during high-speed operation and heavy-load operation.

- Material

Made of high-strength and wear-resistant materials such as ductile iron, polyamide or polyurethane, etc.

- Size and Specifications

A variety of specifications and sizes are available to meet the needs of different cranes & stackers

- Control System

Equipped with advanced control systems to achieve precise control of the stacker.

- Other Parameters

Such as wheel diameter, rim width, bearing type, etc. are also important technical parameters of the wheel set

Features

- High Precision Positioning

Through the integrated advanced control system and sensor technology, high-precision positioning and navigation are achieved.

- High Efficiency Operation

Adopt optimized materials and structures to reduce friction and energy consumption and improve operating efficiency.

- High Load Bearing Capacity

Designed with a high-strength load-bearing structure to ensure stability and safety under heavy-load operations.

- Low Noise & Vibration

Adopts advanced shock absorption and noise reduction technology to effectively reduce noise and vibration.

- Intelligent Management

Usually integrated with warehouse management systems to achieve real-time data transmission and analysis.

- Easy to Maintainance

The design takes into account the needs of easy maintenance and maintenance, reducing downtime and maintenance costs.

- Flexibility & Ddaptability

Provides a variety of specifications and sizes to meet the needs of different stackers and storage environments.

- Enhanced Safety

Equipped with safety protection functions such as overload protection and emergency braking

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.