Crane Bumper

Crane Parts Service

Working Principle: Absorb energy by deformation when impacted, converting it into elastic energy,.

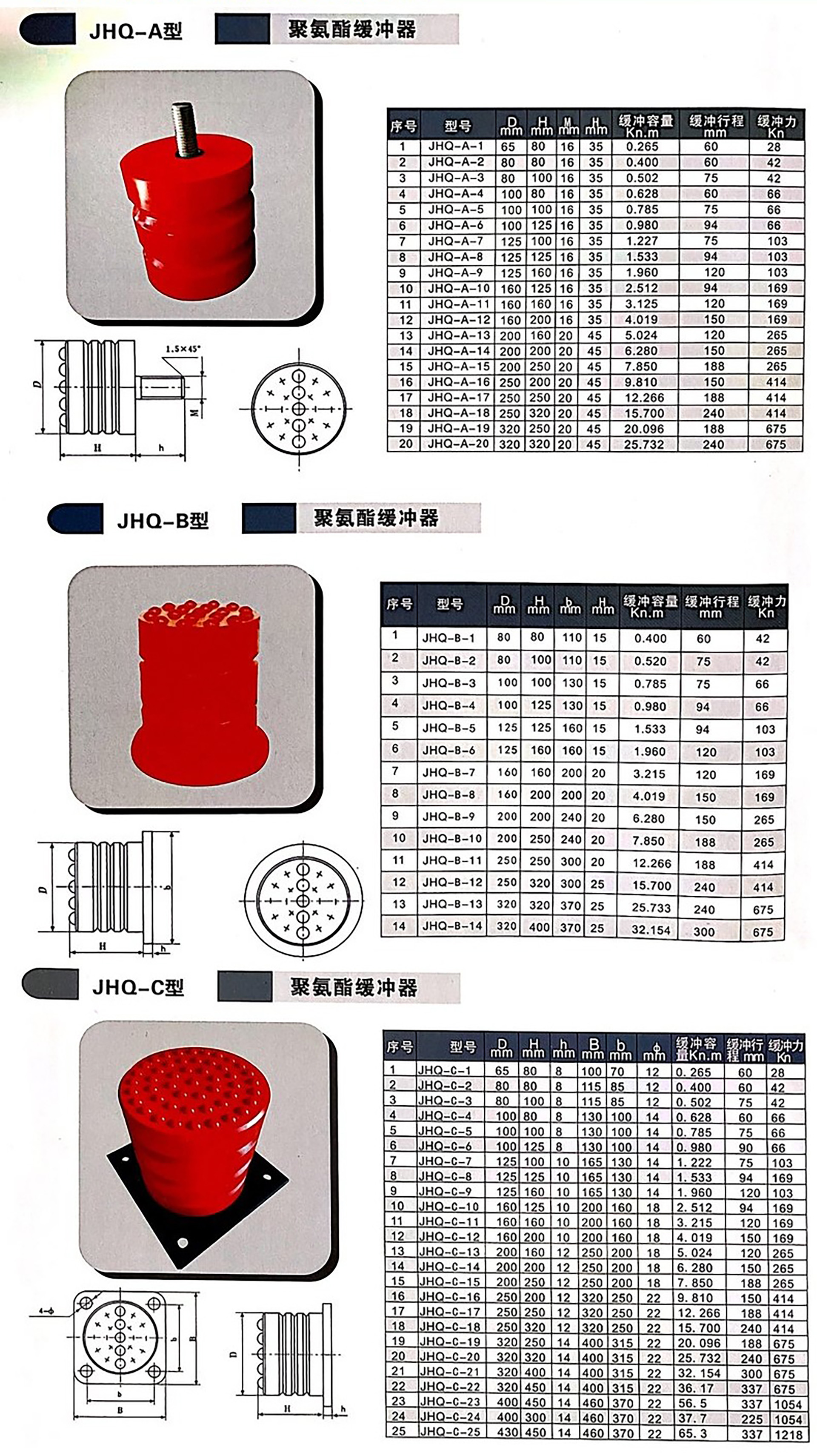

Crane Bumper Type: Stud Type(JHQ-A), Pressure Plate Type(JHQ-B) and Flange Type(JHQ-C).

Material: Polyurethane

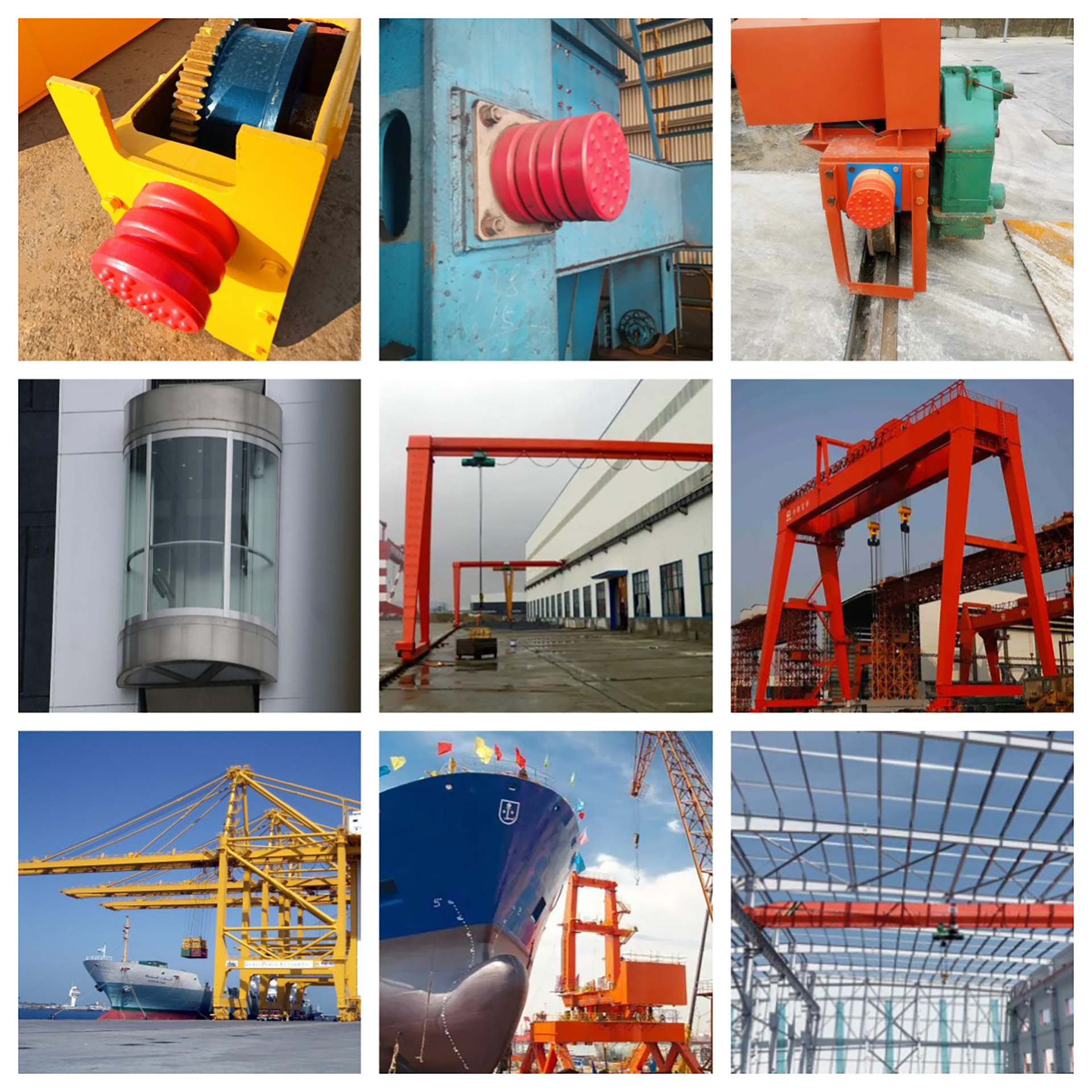

Widely used in various scenarios that require anti-collision and deceleration, such as large industrial machinery, elevators, mining cars, overhead crane, gantry crane and kinds of industrial crane, etc.

Download:

Crane Bumper

Description

Polyurethane crane bumper is a safety device that uses the microporous bubble structure of polyurethane material to absorb energy and buffer. When it is impacted, it is equivalent to a spring with multiple airbags for damping, which can effectively absorb and disperse the impact force, thereby protecting mechanical equipment from damage.

The working principle of polyurethane crane bumper is based on its special material structure. This material has been specially processed to form a microporous bubble structure with excellent buffering performance. When this structure is impacted, it can absorb energy by deformation and convert it into elastic energy, thereby playing a role of buffering and protection.

Crane Bumper have the features as follows,

Lightweight, easy to install, maintenance-free, good buffering effect, good impact resistance and pressure resistance, no noise, no sparks, good explosion-proof performance during the buffering process, safe, reliable and stable. It has become the preferred buffer in the crane and elevator industry.

| Item/Unit | Performance Index | |||

| Density g/cm³ | 0.55~0.65 | |||

| Hardness Shaw A | 60~80 | |||

| Recovery Rate % | >95 Tested after 75% Compression and Unloading for 5 Minutes | |||

| Compressive Strength MPa | 1.2~2.5 Tested, When Compressed to 50% of the nNominal Height | |||

| Working Temperature ℃ | -30~+60 | |||

Technical Specificaton

Usage Instruction

In order to ensure the machinery safety operation, please comply with usage rules of crane bumper

A. Perform Regular Inspections;

B. Avoid using in low temperature (below -40°C) or high temperature (above 80°C) and humidity (above 85%) environments;

C. Do not use in strong acid or alkali environments;

D. Refer to the instruction manual and icons before installing or replacing the crane bumper;

E. The crane bumper installed on the crane should have the collision object and the center of the buffer in the same direction of movement. The end face should be straight and should not be tilted;

F. When the crane buffer is configured as; when the crane buffer collides with the buffer, the buffer of the same diameter should be used, and the longitudinal length of the crane buffer should be kept consistent as much as possible;

G. When installing the crane buffer, a certain amount of space should be left around it to avoid collision, extrusion and other accidents with other structures;

H. The crane buffer should be stored at room temperature and placed in a ventilated and dry place;

I. If the polyurethane is found to be cracked or falling off, it should be replaced in time.

Applications

Crane Bumper is suitable for metallurgy, mining, railways, ports, ships, automobiles, weighing instruments, large machinery, equipment and other fields. It can also be used for the front and rear corners of various cars and vans to prevent collision.

Crane Bumper is suitable for metallurgy, mining, railways, ports, ships, automobiles, weighing instruments, large machinery, equipment and other fields. It can also be used for the front and rear corners of various cars and vans to prevent collision.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.