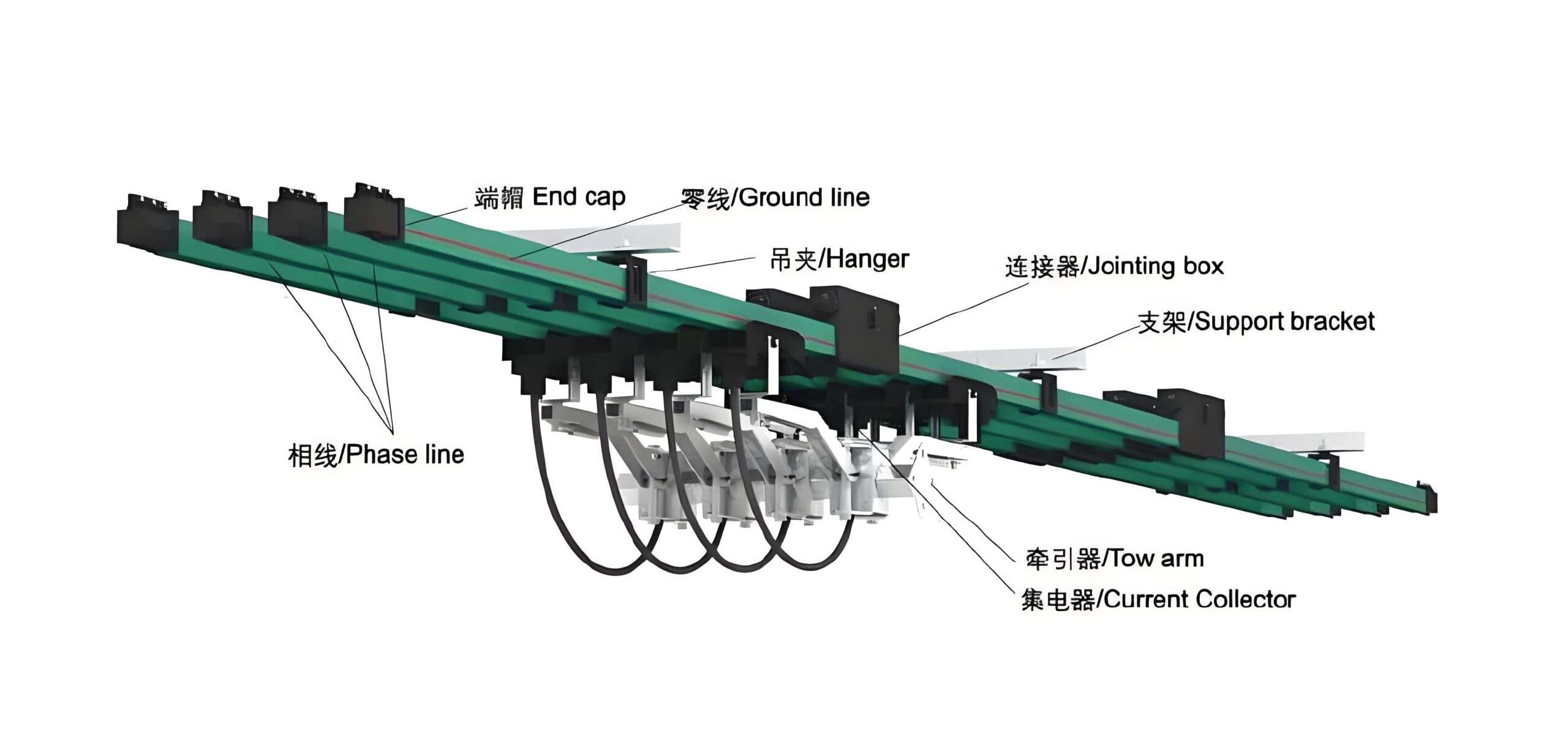

Mobile Conductor Rail System

Cranes Parts

Conductor Material: Copper(5000A) /Aluminum(3000A).

Max Allowable Amper: 5000A/3000A

Poles: 3P/4P/Customized

Bending Radius: ≥1200mm

Temperature: -40℃ To +115℃

Description

The conductor rail system is a modern power supply system using single –pole insulated conductor rails. It complies with the latest regulations and provides the electric energy for mobile consumers. The conductor rail is material copper (200A-5000A), aluminum (150A-3000A). The aluminum conductor rail is provided with a proven and patented stainless steel contact surface.

The conductor rail system can be installed indoor or outdoor. For high temperature conditions, a high temperature insulation cover up to +115°C is available, also for low temperature conditions, it could be up to -40°C. The entire conductor rail system is insulated to current safety regulations, it is entirely protected against direct contact. Ground insulation cover is marked yellow-green on one side over the entire length of the rail. Curves radius R ≥ 1200mm.

1. Busbar Construction:

Busbars are typically made of highly conductive materials such as copper or aluminum. These materials have low electrical resistance, reducing energy losses during power transmission.

2. Configuration:

Busbars come in different shapes and configurations, including flat bars, tubes, or a combination of both. The choice of configuration depends on factors such as the required current-carrying capacity, available space, and design preferences.

3. Insulation:

In some cases, busbars may be insulated to prevent accidental contact and improve safety. Insulation can be in the form of a non-conductive coating or insulating materials around the busbars.

4. Busbar Types:

There are various types of busbars, including main busbars, feeder busbars, and sectional busbars. Main busbars distribute power to major components, while feeder busbars distribute power to specific loads or sections. Sectional busbars allow for isolation and maintenance of specific areas without disrupting the entire system.

5. Connection Points:

Busbars serve as connection points for various components such as circuit breakers, switches, and other electrical devices. They allow for the easy addition or removal of equipment without disrupting the entire power distribution system.

6. Flexibility:

Busbar systems are designed to be flexible, allowing for changes and expansions in the electrical system. This flexibility is crucial in adapting to evolving power distribution needs.

7. Current Rating:

Busbars are designed to handle specific current ratings based on the anticipated load. The size and thickness of the

busbars are selected to ensure that they can carry the required current safely without overheating

Product Features

It is safe and reliable, even if it is touched by fingers, there is no risk of electric shock, and it meets the IP44 standard.

It is safe and reliable, even if it is touched by fingers, there is no risk of electric shock, and it meets the IP44 standard.- Energy saving and consumption reduction, using special formula aluminum alloy profile as conductor; The resistance is small, which can minimize the loss of electric energy.

- Sheath and accessories are common.

- Long service life. The conductor sheath also adopts a unique formula, which greatly prolongs the service life of the unipolar sliding contact wire system.

- Combined design is adopted, which is easy to install and daily maintenance, especially suitable for high-altitude operation.

- The collector can move in three-dimensional space and can meet the uninterrupted power supply of power supply equipment; Double insulation design is adopted for safer and more reliable operation.

- New materials, new technologies and new processes ensure that the products have higher corrosion resistance, acid resistance, weather resistance and working temperature range, and the working performance is safer and more reliable.

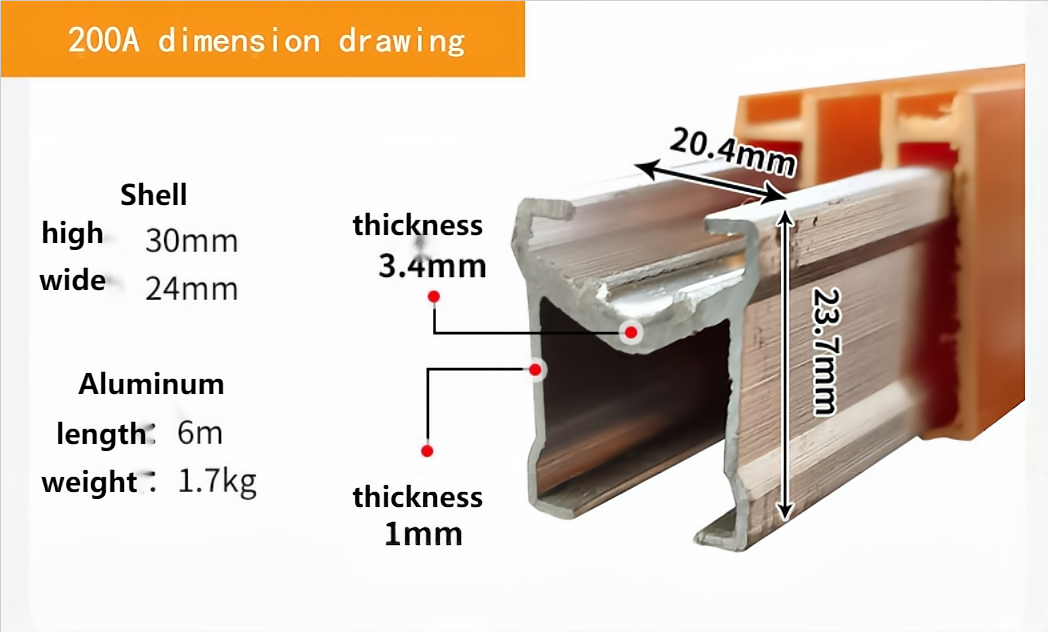

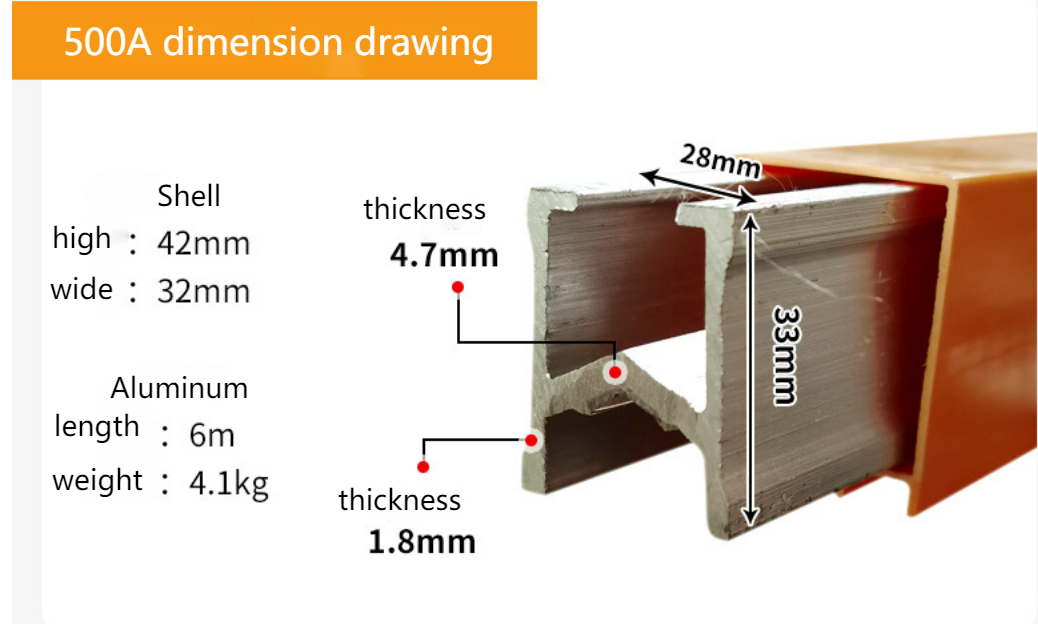

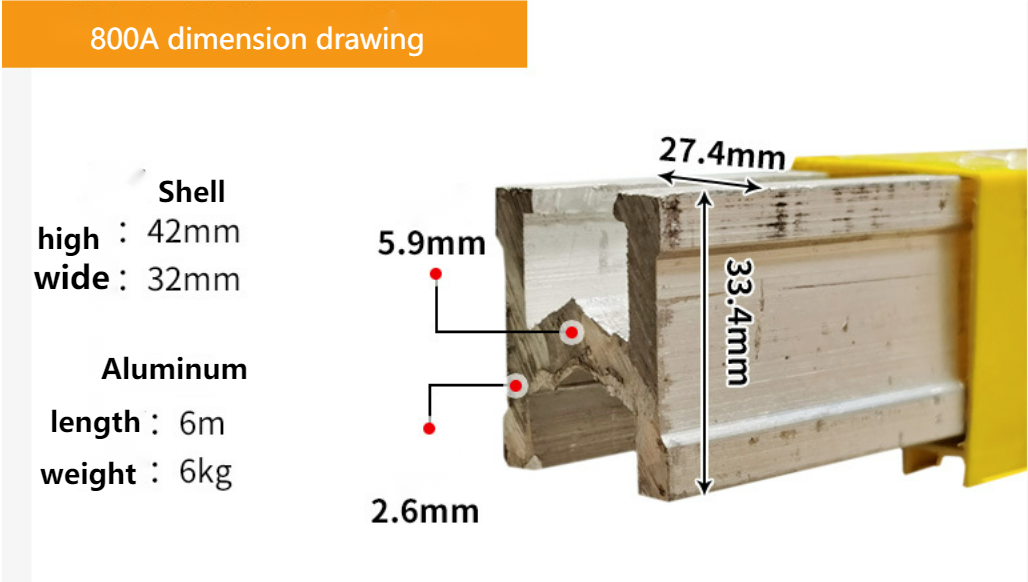

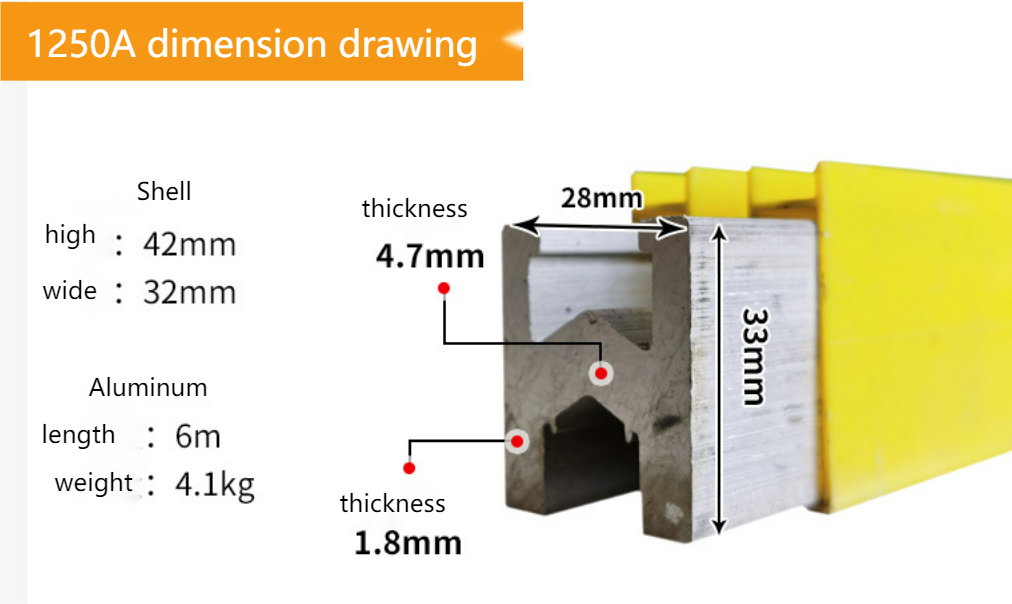

Parameter

Installation & Application

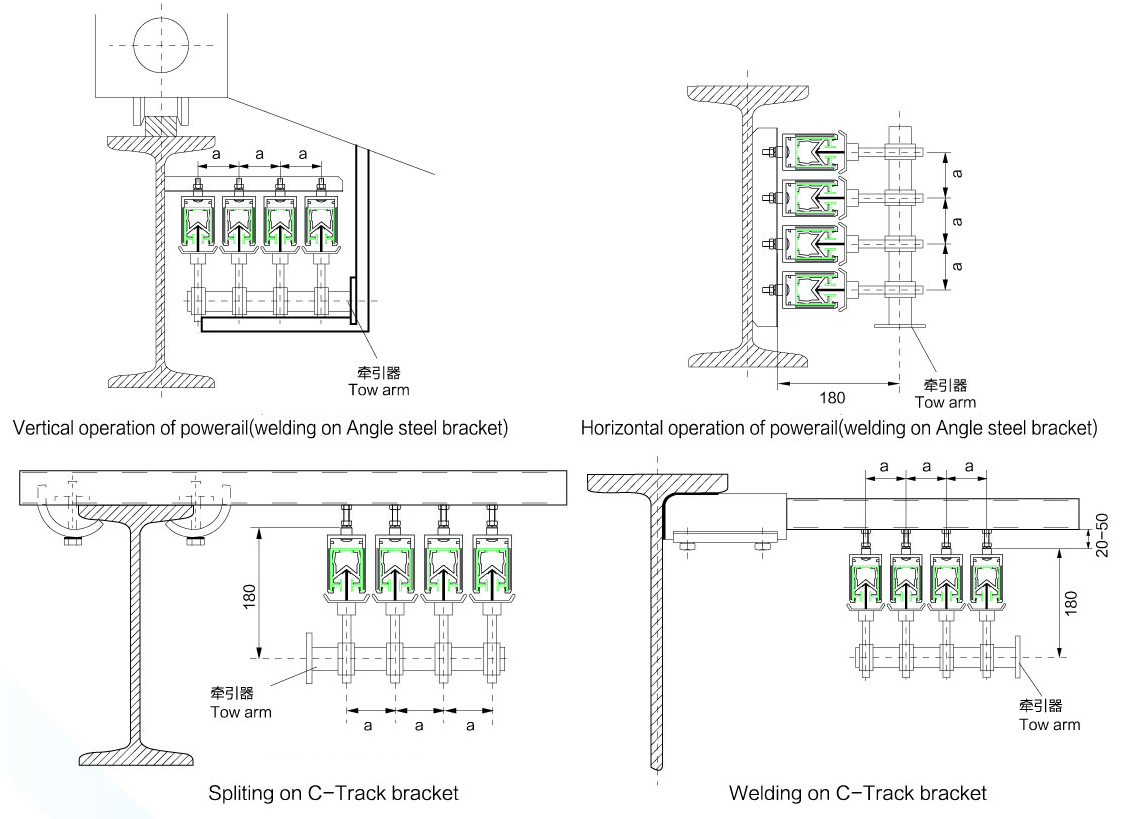

Installation

Horizontal Installation: Suitable for small tonnage cranes, electric hoists and other equipment, with high safety and good application efficiency.

Horizontal Installation: Suitable for small tonnage cranes, electric hoists and other equipment, with high safety and good application efficiency.

Vertical Installation: Suitable for stackers, AGVs, automation equipment assembly lines, etc., requiring on-site production of side-mounted bottom plates and configuration of tensioning devices and angle steel brackets

Application

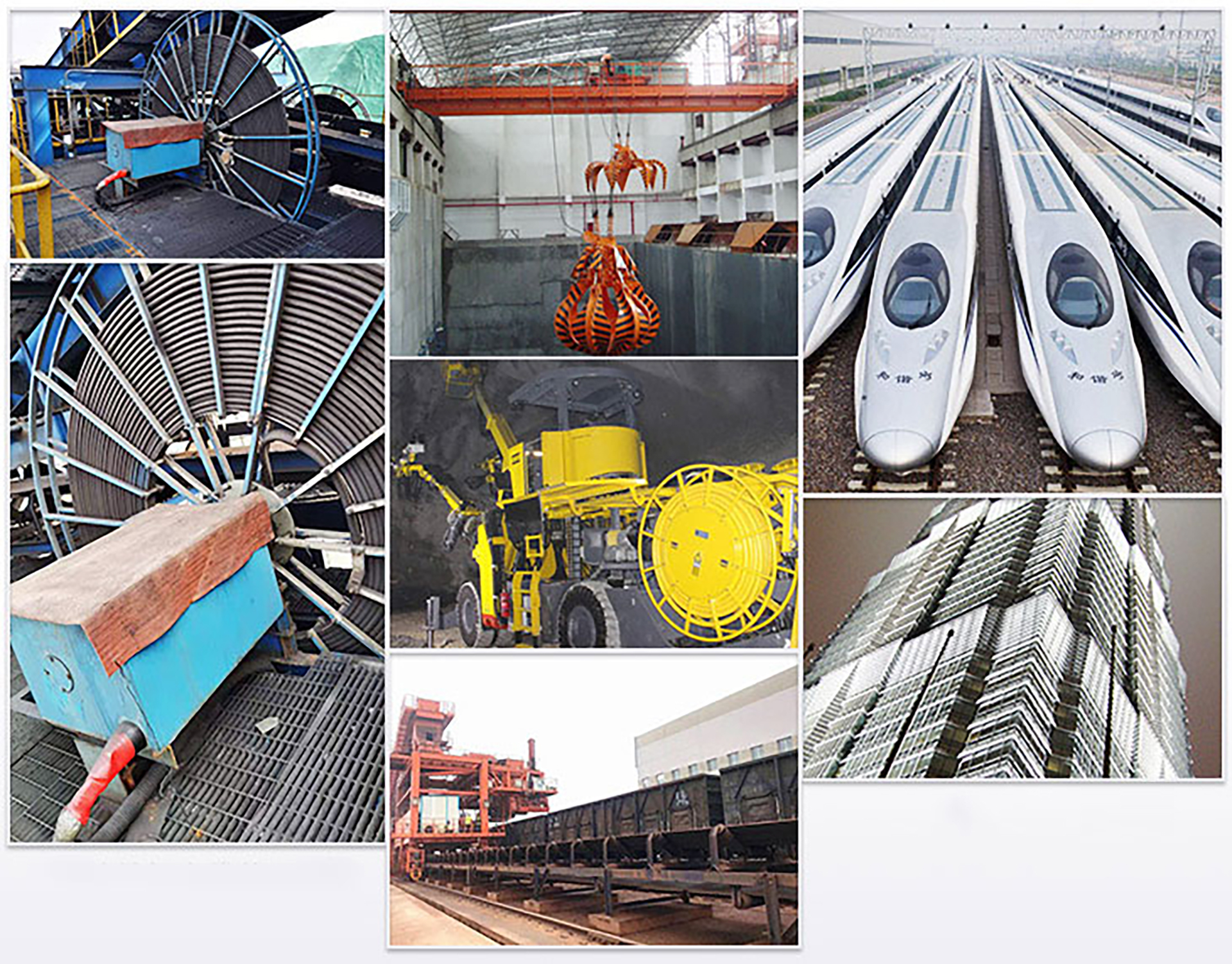

With advanced technology, skillful manufacture and beautiful design, the Flexible Insulated Copper Rail is suitable for machinery works, small size steel factory, low power hoisting, cranes, monorails, electric hoists, electric tools, stacking systems and wildly used in the Lifting industry.

With advanced technology, skillful manufacture and beautiful design, the Flexible Insulated Copper Rail is suitable for machinery works, small size steel factory, low power hoisting, cranes, monorails, electric hoists, electric tools, stacking systems and wildly used in the Lifting industry.

Regular Maintenance

The maintenance and care of seamless busbars is relatively simple, and the following points should be noted:

Regular Inspection: Regularly check the conductivity and insulation performance of the busbar to ensure its normal operation.

Cleaning & Maintenance: Keep the busbar clean to prevent dust and debris from affecting the conductivity.

Replacement of Parts: Regularly replace worn collectors and conductors to ensure the stability and safety of power supply.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.