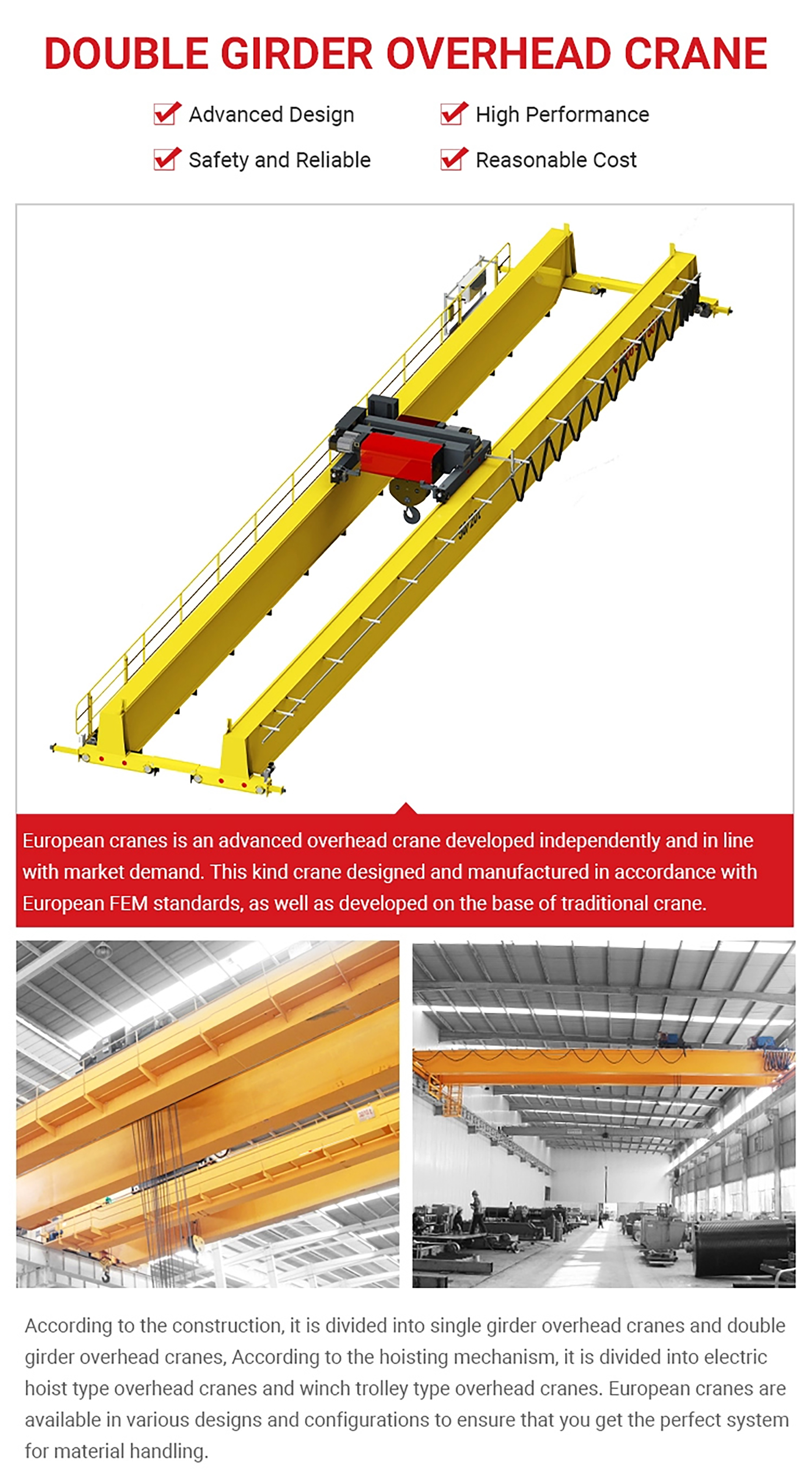

Double Girder FEM Overhead Crane

DESIGN STANDARD: FEM/DIN/ISO

CAPACITY: 1 T -160T

SPAN: UP TP 40 M

LIFTING SPEED: 0-10M/MIN(VFD) OR CUSTOMIZED

CROSS TRAVELING SPEED: 0~60 M/MIN(VFD)

LONG TRAVELING SPEED: 0~120 M/Min (VFD)

CLASSIFICATION/DUTY: FEM 2M/A5-FEM 4M/A7

APPLICATIONS:

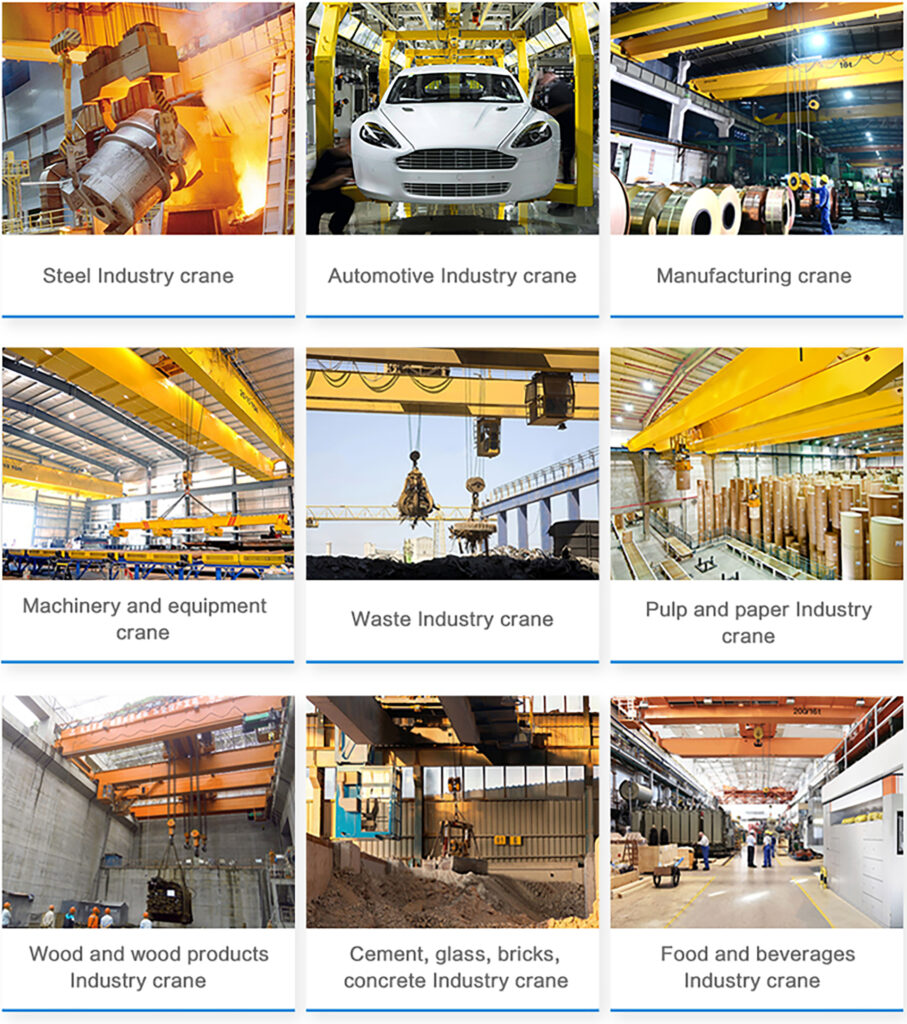

MACHINERY MANUFACTURING, METALLURGY, PETROCHEMICAL, PORTS, RAILROADS, CIVIL AVIATION, POWER STATIONS, PAPER MAKING, BUILDING MATERIALS, ELECTRONICS AND OTHER INDUSTRIES.

DESCRIPTION

In order to ensure the FEM overhead crane excellent performance and ensure the stability, Sinomac Industrial freely update the hoist system as follows,

✅The traditional 3-IN-1 gearbox FREELY UPDATED into Planetary type Gearbox, which save more room space, then improve the utility rate of space.

✅Lifting Speed can be adjusted to meet different clients speed requirement, so that improve the production efficiency.

✅Easier Assemble and Installation-Aviation Plug Connection. In order to be convenient to installed the FEM overhead crane, all the connection adopted the aviation plug connection, which greatly improve the installation efficiency to indirectly save the labor charges cost.

✅All the movement speed is controlled by Inverter to ensure the FEM overhead crane operation stable and extend the motor lifetime.

✅All the electric components adopt the world famous brand, Schneider, ABB, Siemens.

✅ In order save after sales cost and free spare parts stocks, Sinomac Industrial crane and hoist systems has the high spare parts fungibility.

✅The Classification of FEM overhead crane is up to FEM 4M, which is suitable for different working conditions in different industries.

Any Technical Questions or Technical Support or Suggestions from us, please leave your messages.

SPECIFICATION

MAIN GIRDER/BEAM

✌FEM/DIN Standard Design.

✌Raw Material from Famous Steel Mills.

✌CNC Cutting for Complete Cover Plate, Web Plate & Rib Plate, High Deflection Accuracy.

✌High Quality Automatic Welding and NDT Inspection.

✌Shot-blasting Sa2.5 to make sure the paint adhesion.

✌The Main Girder with High Temperature Resistance can be working under the temperature up to 60℃

✌Larger Span Main Girder (Over 12M) can be designed into high strength bolts connection with positioning hole, which can lower the shipment cost and easy to assemble the main girder.

✌The deflection of beam can be designed into 1/1200 of span for high precision lifeting request workshop.

✌Thickness of Paint ≥ 120 μm.

ELECTRIC TROLLEY

✌FEM/DIN Standard Design.

✌Adopted 3-IN-1 Planetary Geared Motor, Lowest Noises, Free Maintenance, Free Lubricant Oil Fill, Lower Headroom.

✌Full Inverter (VFD) Drive. Inverter adopted Toshiba-Schneider Inverter Company

✌Galvanized Steel Rope adopted the crane industrial famous brand. High Strength 2160N/m2 with long Service Life and 1.8 times safety factor.

✌The Hook Block adopted the forged hook, Material of hook: 35CrMo.

✌The Brake Type- Electromagnetic inserted into the motor which have the automatic brake, if the power is fault.

✌Hoist has the up/down limiter, cross travel limiter and overload limiter to make sure the safety.

✌The Duty/Classification is up to FEM 4M/ISOM7.

END CARRIAGES/BEAMS

✌FEM/DIN Standard Design

✌Rectangular Tube Structure, None Welding.

✌Overall process is completed by boring and milling CNC lathe, which has high precision and uniform force advantages.

✌Wheel is made of forged 42CrMo alloy steel, which is overall quenching and tempering treatment with wear resistance and high hardness advantages.

✌Wheel bearings adopt self-aligning tapered roller bearings, which can automatically adjust the level of the crane.

✌The drive adopts a 3-IN-1 GEARED MOTOR, which is completely sealed compact gearbox with free of maintenance for life. the geared motor and the end carriages are assembled with a torque arm, which has the advantages of high transmission efficiency and low noise.

✌The motor reducer adopts a squirrel-cage variable frequency motor, with protection grade IP54, F class insulation, stepless speed regulation, hard tooth surface, quiet design, good sealing, and stable operation.

ELECTRIC CONTROL SYSTEM

✌The electric cabin protection class can be up to IP67.

✌All the Main Electric Component is adopted Schneider/ABB or equivalent.

✌All wires have color, number, or wire size marks, which can be easy identified.

✌All the movement is controlled by Inverter (VFD), the Inverter is adopted the TOSHIBA-SCHNEIDER Brand or your specified brand.

✌Cross Travel is adopted festoon type power system with galvanized sliding rail and cable trolley.

✌All the same bay cranes will be equipped the infrared anti-collision limit switch.

✌Equipped sound and light alarm system, Emergency stop, lower voltage protection, phases failure protection, Phase lose protection, voltage fluctuation Protection system and current overload protection.

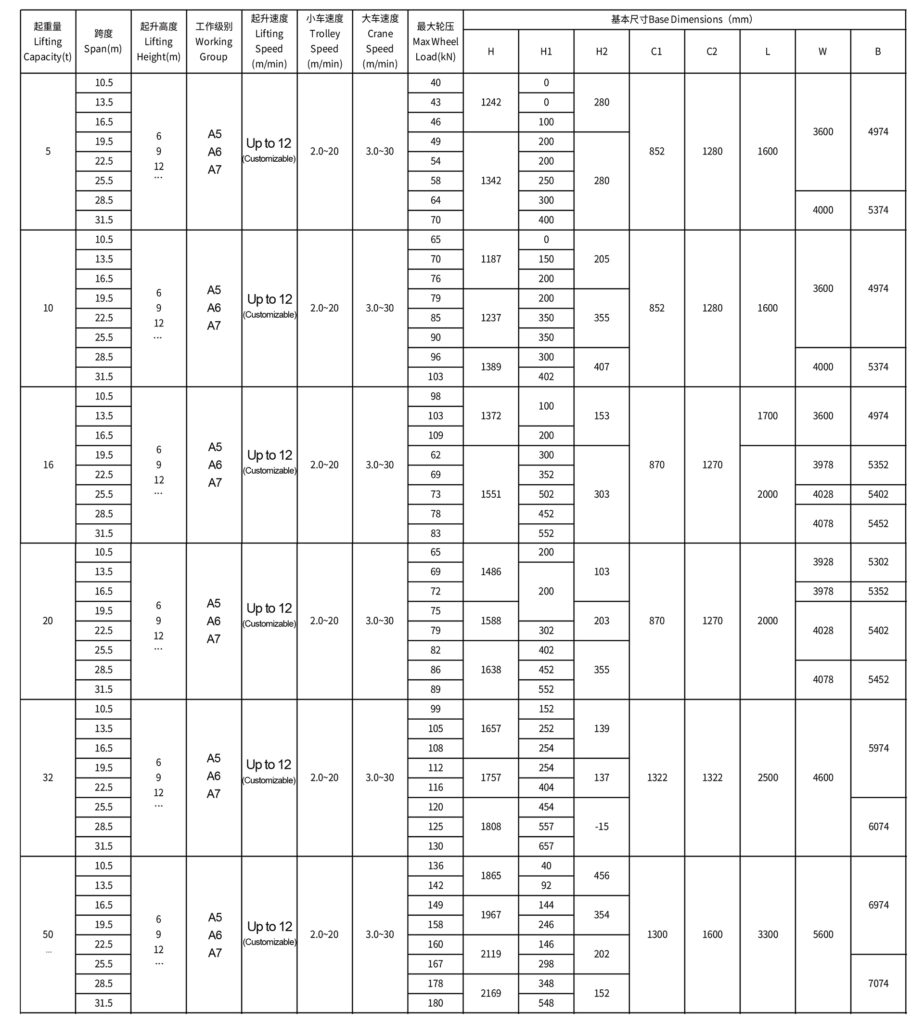

TECHNICAL SPECFICATION

FEATURES

- Low Headroom

- FEM/DIN Design Standard

- Welding Box Girder/Beam.

- Full Inverter Speed Control

- 3-IN-1 Gearbox With Frequency Motor

- IP55 Protection, F/H Insulation

- Heavy Duty Motor, 60%ED rating

- Overload Cell with Display

- Up/Down Limit Switch

- Electromagnetic Brake System

- DIN 34CrMo4 Hook, Class T

ADVANTAGES

1. Light Dead Weight

Design software developed by the company combine with three-dimensional modering and finite-element analysis, apply the reasonable structure to lifting mechanism, steel construction and accessories, together with wide use of high-strength material, it increases load capacity, decreases self-weight and has lower weight and wheel pressure than that of traditional crane.

2. Small Hook Approchal

Limit distance from hook to boat sides is short but has large working arrange. with lower height above the rail, it makes full use of space of factory building,

3. Low Cost of Running & Maintainance

As with low wheel pressure and small dimension, it reduces investment of previous construction including factory building, and also reduces illumination and heating expense. The reilable performance and durability also minimizes the additional charges for the use of product at the later stage. Selected components with high quality and preformance lower the maintenance and repair. The total power consumption is reduced, which achieves cost savings.

4. High Performance

Use variable-frequency technology, run with heavy load at low and light load at high speed. The adjustable speed ranges in 1:10, which ensures eot crane/FEM overhead crane run steadily and reduces impact on factory building. Combination of swing-proof technology achieves a high accuracy position of lifting items.

Customized

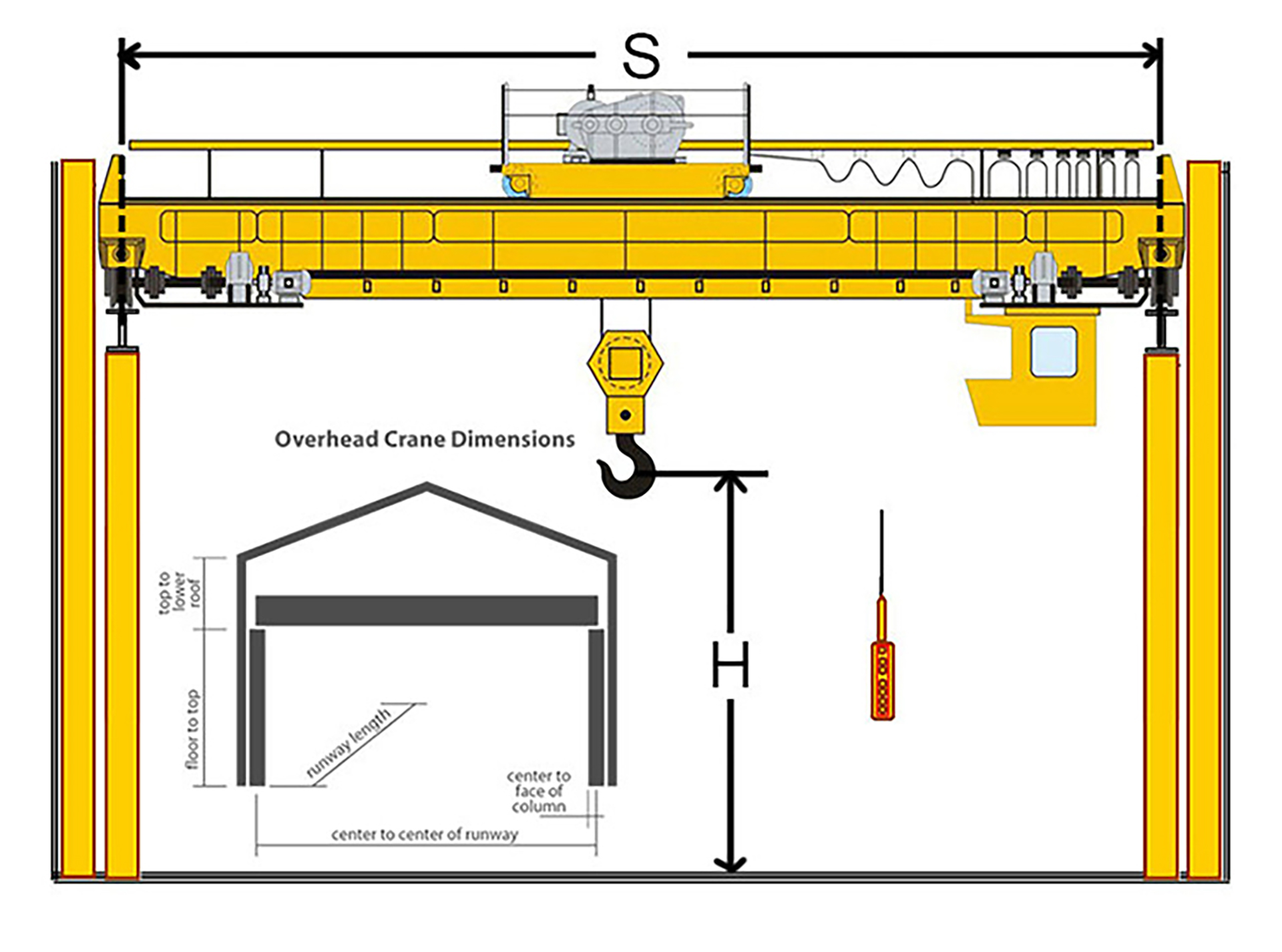

Please share following specificatons of FEM overhead crane, so that you can get the best price from us.

1.Capacity?

2.Single Girder or Double Girder?

3.Lifting Height?

4.Span(Rail Center to Rail Center)

5.Classification/Duty or Working Condition as follows,

a. Average Lifting Weight?

b. Lifting Times/Hour?

6.Power Supply: 3PH220V/380V/415V/440V/460V OR?

7.Travel Distance? Whether the Long Travel Power System-Conductor Rail and Crane Traveling Rail are required?

8.Service Area(Hazardous Area, Temperature)?

9. Please share Workshop Drawing, if it’s Possible?

10. Your Other Special technical specifications request?

APPLICATION

Double girder FEM overhead crane are widely used to handle materials in many industries’ workshop and warehouse; such as machinery manufacturer, warehouse, logistic, paper making, electronics industries workshop and other material handling situations.

If you have any questions or would like more information for our double girder overhead cranes, please don’t hesitate to contact us. We will provide proffesional suggestions to select the right crane.

OTHER RELATED PRODUCTS

Related Products

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.