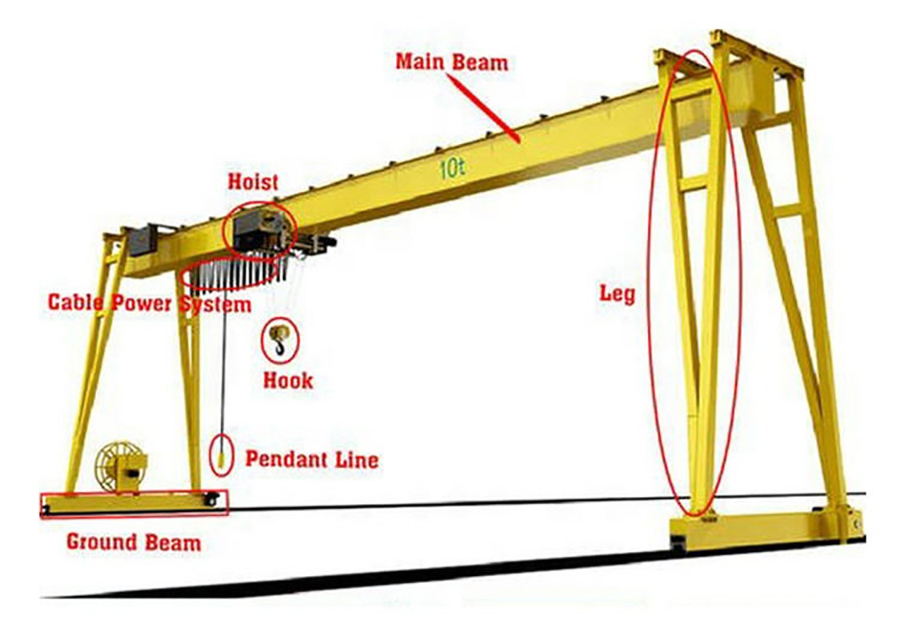

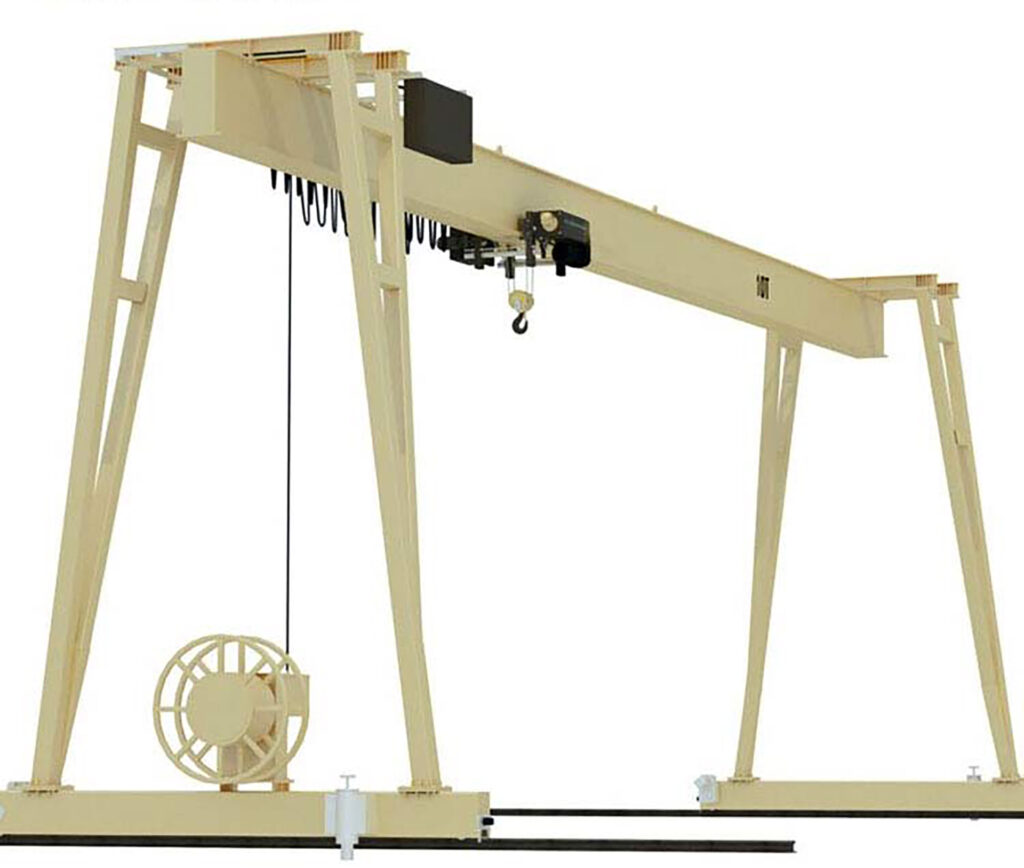

1-20 Ton Light Gantry Crane

Capacity: 1~20 Tons

Lift height: 3~40m

Span: 5~31.5m(Max 35m)

Work duty: A3~A6

Protection class: IP54-IP65

Working temperature: -40~+40℃

Description

1-20Ton Light Gantry Crane is ideal for lifting and transferring small and lightweight loads for both indoor and outdoor applications. Under normal circumstances, the lifting weight is below 20 ton (common ones are 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 15 ton and 20 ton gantry cranes), the span is within 35m, and there is no special requirement for use. It is advisable to choose light duty gantry crane.

1-20 Ton light gantry crane comes in multiple configurations and designs to suit varied needs of customers, including single girder gantry crane, semi gantry crane and portable gantry crane system.

Technical Data

| Loading Capacity | 0.5~20t |

| Lifting Height | 3~30m or customized |

| Lifting Speed | Single speed: 3~8 m/min or customized |

| Variable speed: 1/10 m/min or customized | |

| Span | 3~35m |

| Left Cantilever | 0~4m or as require |

| Right Cantilever | 0~4m or as require |

| Lifting Mechanism | Wire rope hoist or electric chain hoist |

| Work Duty | A3~A6 |

| Power Supply | AC-3Phase-220/230/380/400/415/440V-50/60Hz |

| Control Method | Ground handle control(Push button), wireless remote control, cabinet control |

| Application Area | Factory,workshop,warehouse,power station,logistic,etc. |

| Color | Customized |

| Working Temperature | -40~60℃ |

| Protection Class | IP54; IP55; IP65 |

Feature

- Stepless control

- Hardened gear

- Motor protection class IP55

- Heavy duty motor, 60%ED rating

- Electromagnetic disk brake, dust proof

- No oil leakage, self-adjustable brake

- Heavy duty galvanized wire rope

- Outperforming reliability designing

- Smaller size, lighter wheel load

- Control mode: pendant/remote/cabin

- Maintenance free

Application

1-20 ton light gantry crane with hoist is widely used for the workshop, station, port, warehouse and , etc. It is used for loading and unloading between fixed span and it can handle many kinds of materials, such as steel structure, precast concrete, glass, plastic, etc.

Buyer Guide For Gantry Cranes

1. Selection of gantry crane

Comply with the relevant regulations of FEM/DIN for 1-20 ton light gantry crane.

Under normal circumstances, the lifting capacity is less than 50t, the span is less than 35m, and there are no special requirements for use, the single main beam type should be selected. If the width of the gantry leg is required to be large, the working speed is high, or the heavy and long pieces are often lifted, the double girder gantry crane should be selected.

2. Span and cantilever length of gantry crane

The span of the gantry crane is an important factor affecting the quality of the crane itself. In the selection, the span should be minimized under the premise of meeting the equipment use conditions and meeting the span series standards.

3. The principle of determining the wheelbase

(a) It can meet the stability requirements of the gantry along the direction of the crane track;

(b) The overall dimensions of the goods should be able to smoothly pass through the flat steel frame of the outriggers;

(c) Note that the wheelbase B is proportional to the span S. Generally, the wheelbase B=(1/4-1/6)S.

Fourth, the gantry crane spacing size is determined

During work, there should be a certain amount of space between the external dimensions of the gantry crane and the passage of goods and transport vehicles in the yard to facilitate loading and unloading operations. When loading and unloading within the span, the general transport vehicle should keep a distance of more than 0.7m from the door leg. When the spreader is not working, there should be a distance of more than 0.5m from the transport vehicle, and when the goods pass through the door legs, there should be a distance of more than 0.5m.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.