Thank you for your trust and inquiry. Before providing a quote for the portable gantry crane, we would need the following information:

Span( S )=_____mm?, Height(H)_____mm? Lift Capacity____kg?

Crane Control: Electric/Manual ?

Electric: Voltage? If electric control, please provide the voltage (V), Hz, Phase.

Hoist Lifting Operation: Electric/Manual?

Span Adjustment: ? Min.____mm? Max.____mm?

Height Adjustment: Adjustment Range? Min.____mm? Max.____mm?

Adjustment Method: Manual Winch/Manual Worm Gear/Electric Worm Gear (Load Lifting)?

Outdoor Sandstone Wheels?

360-degree Rotation on the spot?

Through the information collected above, we can understand your specific requirements to provide accurate pricing and solutions tailored to your needs.

1. Q: Should I choose an aluminum or steel crane?

A: Both types of metal offer their own benefits. Steel is stronger, but aluminum gantry crane is lighter and also more corrosion resistant, making it better suited for lighter and outdoor applications.

2. Q: Are your products certified?

A: Yes, we provide complete compliance statements and test certificates for all our cranes and lifting equipment, along with documentation on how to safely operate the equipment.

3. Q: What payment options do you offer?

A: We currently accept payment by credit or debit card; bank transfer (TT), and more.

Thank you for your interest and cooperation. Have a question about Mini Gantry Cranes or need a quote? Contact us WhatsApp: 0086-16650358998 today for personalized assistance and expert guidance. Let’s find the perfect solution for your lifting needs together!

This article will delve into the essential requirements and common questions customers should consider before purchasing crane grab buckets. We’ll detail the prerequisites for quoting, such as grab material, density, application, and discuss the drive types, lifting equipment, and other specific requirements, aiding customers in preparing thoroughly for the inquiry process.

Before providing a quote for the crane grab, we would need the following information:

Q: What materials can the crane grab handle?

A: The crane grab can handle various materials such as steel, wood, and concrete.

Q: What is the lifting capacity of the crane grab?

A: The lifting capacity of the crane grab ranges from 1 ton to 10 tons, depending on the model.

Q: What types of surfaces or environments can the crane grab work on?

A: The crane grab is designed to work on a variety of surfaces, including smooth, rough, and uneven terrains.

Q: How does the crane grab attach to the lifting equipment?

A: The crane grab attaches to the lifting equipment using a quick coupler or hook attachment.

Q: What are the maintenance requirements for the crane grab?

A: Regular maintenance such as greasing moving parts and inspecting for wear and tear is required for the crane grab.

Q: Is the crane grab compatible with different crane models?

A: The crane grab is compatible with most standard crane models and can be easily integrated into existing systems.

Q: Does the crane grab come with any safety features?

A: Safety features of the crane grab include overload protection, emergency stop buttons, and safety locks.

Q: Can the crane grab be operated remotely?

A: Remote operation of the crane grab is possible with the addition of a remote control system.

Q: What is the lead time for ordering and delivery of the crane grab?

A: The lead time for ordering and delivery of the crane grab is typically 4-6 weeks, depending on customization requirements.

Q: Are there any specific installation requirements for the crane grab?

A: Installation requirements for the crane grab include proper alignment and securing to the crane’s hook or attachment point.

Q: What is the warranty period for the crane grab?

A: The warranty period for the crane grab is 1 year from the date of purchase, covering manufacturing defects and faulty components.

Q: Does the crane grab come with any certifications or compliance standards?

A: The crane grab comes with CE certification and compliance with industry safety standards.

Q: Can the crane grab be customized to specific requirements?

A: Customization options for the crane grab include different jaw configurations, sizes, and materials based on specific requirements.

Q: What is the lifespan of the crane grab?

A: The lifespan of the crane grab is approximately 5-10 years with regular maintenance and proper usage.

Q: How does the pricing of the crane grab vary based on different configurations or options?

A: Pricing for the crane grab varies based on factors such as lifting capacity, material, and additional features, with customized options available at an additional cost.

Have a question about Cranes grab or need a quote? Contact us today for personalized assistance and expert guidance. Let’s find the perfect solution for your lifting needs together!

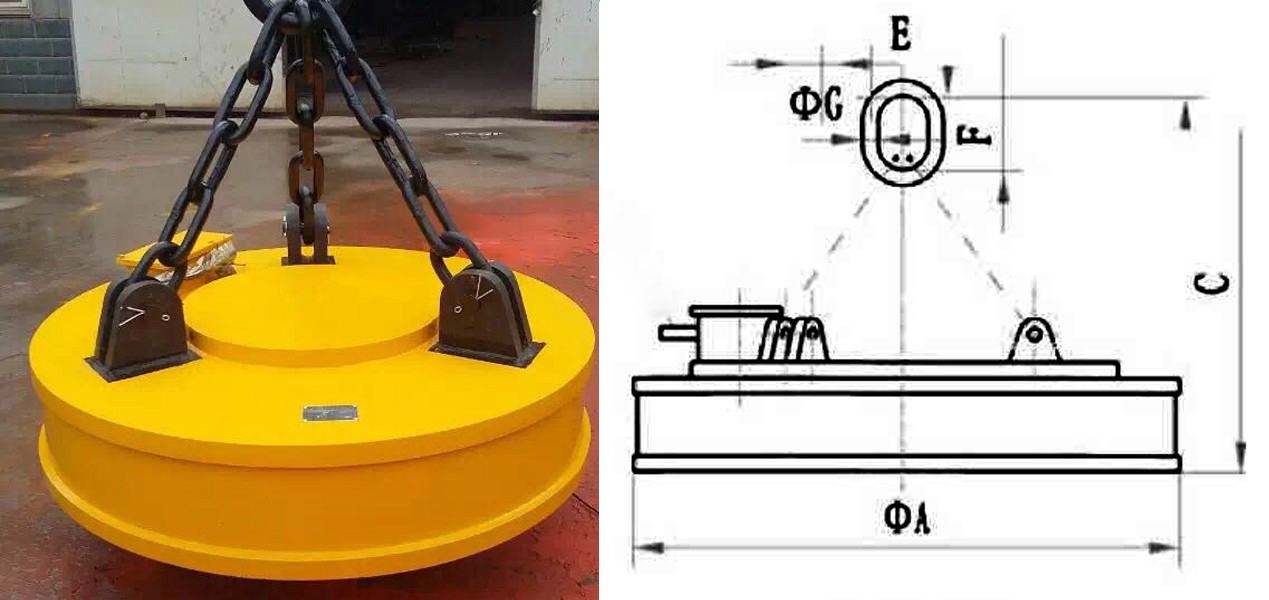

To help you get the suitable scrap magnet for your application, you are requested to give following information:

1. What shape of material are to be handled?

For example: steel scraps, bloom, plate or bar.

2. What are the dimensions & temperature of the load material?

3. Load capacity__ton?

4.Power supply:__V/__HZ/__ phase

5. Applicable crane types:___

A: overhead crane B: gantry crane C: jib crane D: excavator

6. Whether need cable reel: ____(A: Yes B: No)

7. Cable length between Magnets to controller: ___m?

8. Other requirements:______?

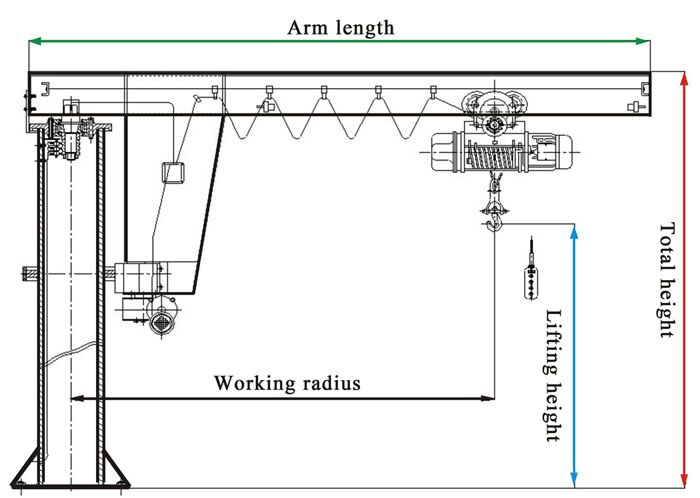

I need a jib crane, what’s the information should I provide when inquiry?

The more information you provide, the accurate solution we can prepare for you!

1.Load capacity__ton?

2.Lifting height__m?

3.Working radius__m?

4.The angle of rotation___?(0-180°/0-270°/0-360°)

5.Power supply:__V/__HZ/__ phase.

6.Arm length__m?

7.Application Scenarios:______?

8.Hoist Type? Wire rope hoist? Chain host?

9.Other requirements:______?

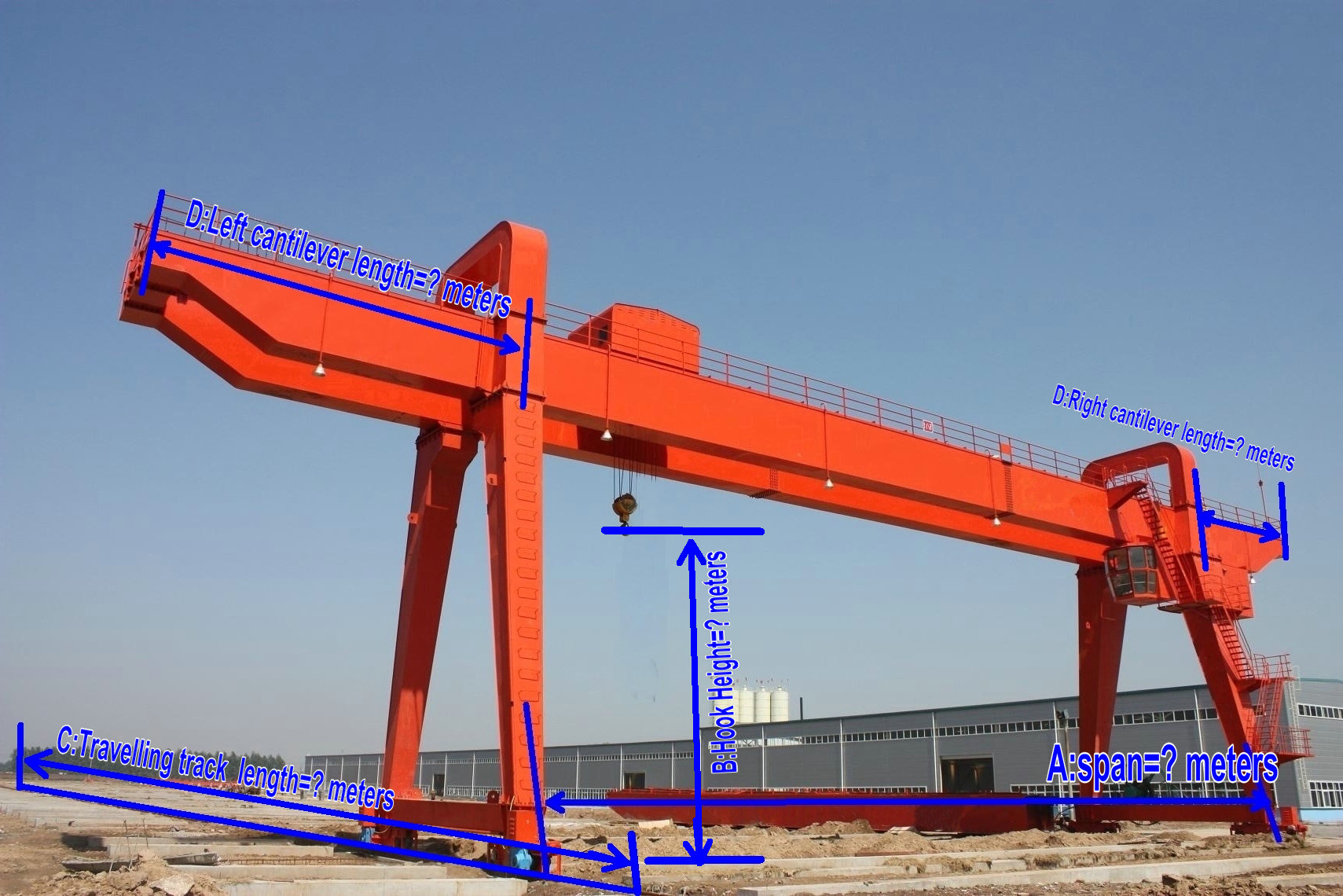

I need a gantry crane, What data do I need to provide?

To provide you more accurate, and suitable proposal soonest, please confirm some questions as below:

1.Load capacity__ton?

2.Single girder or double girder gantry crane?

3.Lifting height__m?

4.Span:__m?

5.Left or right cantilever length__m?

6.Power supply:__V/__HZ/__ phase.

7.Travel distance ? do you need to buy the travel rails from us also?

8.Application Scenarios:______?

9.How many operating hours per day?

Does it work at full load? If not what is the full load percent?

( Operating hours__/day? Full load__%?)

If possible, please share some photos of crane working site.

What’s the information should I provide when inquiry?

The more information you provide, the accurate solution we can prepare for you!

1.Lifting capacity__ton?

2.It is single girder or double girder overhead crane?

3.Lifting height__m?

4.The Span of the main girder?

5.Power supply: in china is 380V/50Hz/3phase ,how about in your factory?

6.Travel distance ? do you need to buy the travel rails from us also?

7.Application Scenarios:______?

8. How many operating hours per day?

Does it work at full load? If not what is the full load percent?

( Operating hours__/day? Full load__%?)

If possible, please share some photos of crane working site.

The type, structure, raw material and production process of wire rope depend on its application. General steel wire ropes use carbon steel wires with a diameter of 0.1 to 6.0 mm and a circular section. When twisting sealed and semi-sealed wire ropes, Z-shaped and other special-shaped wires are used. The types of wire ropes are divided according to their purposes: there are wire ropes for suspension bridges and mine wire ropes, aerial cableway use wire ropes, traction wire ropes for transmission devices, wire ropes for elevators, wire ropes for bundling and dragging goods, etc. The variety of wire ropes is increasing, and the structure is increasingly complex. In addition to various coated steel wires, stainless steel wires and bimetallic steel wires are also used. In order to ensure the safety and reliability of the use of steel wire ropes, the steel wire ropes are required to have sufficient strength, good flexibility, compactness of twisting, compression resistance, wear resistance, corrosion resistance and fatigue resistance, among which strength is the most important.

The selection of wire ropes should meet the following requirements:

① Generally, the left and right intertwined wire rope is used so that it will not twist and loosen when lifting the goods, and it must have a quality certificate.

②The steel wire rope with asbestos core should be used for lifting and transporting hot or molten metal wire rope.

③The hoisting and luffing mechanism shall not use braided and jointing in length steel wire ropes. When other wire ropes need to be jointed, it must be ensured that the connection strength of the joint is not less than 90% of the breaking force of the wire rope, and it must not pass through the pulley into the drum.

When the wire rope meets one of the following conditions, it should be scrapped:

① The number of broken wires of the wire rope in one twist pitch exceeds 10% of the total number of wires.

②The wear amount of the outer steel wire exceeds 40% of the original diameter. When it is insufficient, it can be scrapped according to the number of broken wires after dismantling.

③ The number of broken wires of wire ropes for lifting hot metal or dangerous goods reaches half of the scrapped broken wires for general lifting equipment wire ropes, including the reduction of surface corrosion of steel wires.

④ The diameter of the wire rope is reduced by 7%.

⑤ The whole strand of the wire rope is broken or the fiber core is exposed, the partial outer steel wire is stretched out in a cage-like or hard knot state.

When replacing an old wire rope, the qualified original design model, diameter, nominal tensile strength and wire rope must be used. If only the same diameter is satisfied and other requirements are lower than the original specifications, the service life of the wire rope will inevitably be affected.

It is forbidden to use wire ropes without qualified certificates. If the diameter of the wire rope does not conform to the original design, it must first ensure that the total breaking force is equal to the original design, and then the difference of the diameter should not exceed: 1mm when the original diameter is less than 20mm and 1.5mm when the original diameter is over 20mm. Too much thick than its original will cause the wire rope to rub against each other when it is wound on the drum and increase the wear and tear.

When replacing or winding the wire rope, please be careful not to let the wire rope knot. Practice has proved that the knotted wire rope is most likely to wear and break during use. It is forbidden to connect two steel wire ropes in the hoisting mechanism.

You can learn about the advantages of our wire rope products, which have various excellent characteristics suitable for a range of applications, such as heavy lifting and supporting suspension bridges. If you require wire rope solutions, please feel free to contact us.

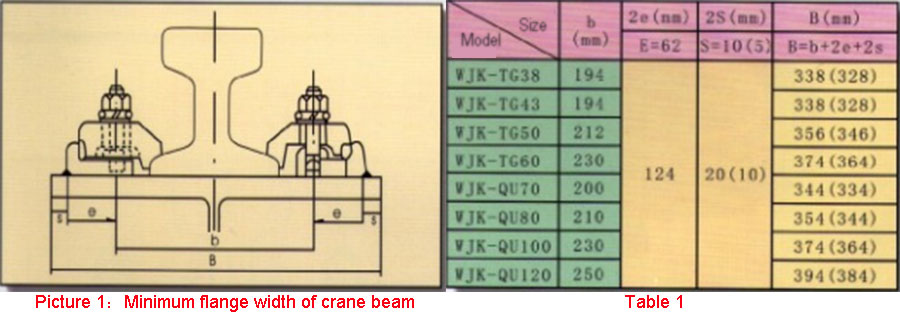

Simple overview:

Specific method:

(1) According to the rail model proposed by the process, select the corresponding crane track rail climps model.

| Rail Model | Crane Rail Climps Model | Rail Model | Crane Rail Climps Model |

| TG38 | WJK-TG38 | QU70 | WJK-QU70 |

| TG43 | WJK-TG43 | QU80 | WJK-QU80 |

| TG50 | WJK-TG50 | QU100 | WJK-QU100 |

| TG60 | WJK-TG60 | QU120 | WJK-QU120 |

(2) The base plate of the crane rail climps are welded with the crane beam, and the selection of the electrode type should be compatible with the material of the connecting piece. For example, when using Q325 or Q345 steel, use E4315 or E5015 electrodes respectively.

The intermediate working crane adopts the welding seam on both sides. Heavy-duty (extra-heavy) working cranes use three-sided surrounding welds.

(3) The minimum width of the upper flange of the crane girder required for the connection of the rail by the crane track rail climps is shown in Picture 1: the “b” value in the figure is found in Table 1.

Note: In Table 1, (a) The dimensions in parentheses in the table are only the minimum width of the upper flange of the weld on both sides of the base.

(b) The B value does not include the dimensions associated with the crane girder braking system.

(4) Distance “a” from the center of the T-bolt of the crane track rail climps to the center of the rail.

| Crane Rail Climps Model | a(mm) |

| WJK-TG38 | 97 |

| WJK-TG43 | 97 |

| WJK-TG50 | 106 |

| WJK-TG60 | 115 |

| WJK-QU70 | 100 |

| WJK-QU80 | 105 |

| WJK-QU100 | 115 |

| WJK-QU120 | 125 |

(5) Base plate positioning. The base plate is arranged at a distance of 600mm or 500mm along the direction of the crane rail; the vertical rail direction is positioned according to the value “a” between the center of the T-bolt and the center of the rail.

(6) Welding base plate

(7) Assemble the crane track rail climps in the following order:

The T-bolt is in place → the adjustment plate, the upper cover plate → the flat washer → the spring washer → the nut → the T-bolt is tightened → the adjustment plate is adjusted as a whole → the T-bolt is finally tightened.

(8) T-bolts are installed and tightened, and the spring washer is finally pressed until the height difference at the joint is 2mm.

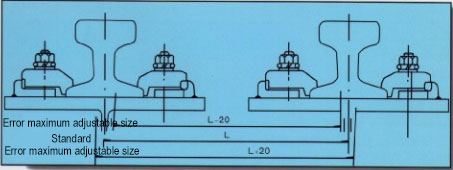

(9) The maximum adjustable size of the gauge is shown in the figure below.

(1) The WJK type crane track rail climps’ base plate is welded with the upper flange plate of the steel crane girder by three-sided surrounding welding or two-sided side welding, which can ensure that the lateral force of the crane is smoothly and evenly transmitted to the crane girder. Moreover, the defect of weakening the flange section caused by a large number of openings in the flange of the crane beam is avoided. Therefore, the section strength and bearing capacity of the crane beam are effectively improved.

(2) The WJK type crane track rail climps’ base plate and the lower end of the T-bolt form a spherical hinge connection. Therefore, under the action of lateral force, the T-bolt is kept perpendicular to the upper cover plate, and deflection is allowed. It can reduce the damage of the lateral impact force of the crane to the rail, crane beam and braking system and other structures. Thereby extending the service life of the structure.

(3) The WJK type crane track rail climps are equipped with a gauge adjustment plate for adjusting the gauge. It can improve the installation accuracy and reduce the unevenness deviation of the rail centerline. It has a two-way self-locking function to prevent loosening during use.

(4) The WJK type crane track rail climps’ bolts and the upper cover plates are free to disassemble and assemble, which provides extremely convenient conditions for construction, installation and maintenance.

(5) The WJK type crane track rail climps’ upper cover plate is consistent with the curvature of the rail section, which can not only compress the rail, but also does not prevent the rail from sliding slightly in the longitudinal direction.

(6) There are two materials for the base plate of the WJK type crane track rail climps:

① ZG270-500 material, the bolt is C grade, the tightening torque is 150N.m, and the maximum lateral force acting on each wheel pressure is 45KN;

② ZG16Mn material, bolts are grade 8.8, the tightening torque is 220N.m, and the maximum lateral force at each wheel pressure is 55KN.

WJK crane track rail climps material should be specified when ordering to prevent the effect.

(7) Crane beam structure: WJK type crane track rail climps are mainly used for steel crane beam rail fixation, and can also be used for the transformation of old concrete crane beams and track rail transformation of ground transportation equipment.

For the cranes parts of overhead crane, gantry crane or EOT crane that have been closed for a long time. Rust prevention is very necessary and important. But how should they can anti rust for a long time ?

The following measures are for your reference :

■ When the crane equipment is shut down for maintenance, the surface of the entire crane equipment must be inspected. It is best to ensure that all parts of the whole crane are covered with a surface film.

■ During the crane inspection, if some film damage is found on the metal structure of the crane, the damaged area should be cleaned and painted with anti-rust paint. When it rains or snows, the metal surface will not be corroded due to weather problems. The rain cover can also effectively prevent rain and snow from corrosion.

■ In the process of rust prevention, please do not neglect the activities of the crane, this is very important. For these spare parts of the crane, you can use -10 or -20 diesel brushing, which can not only remove materials that are prone to corrosion of the equipment, but also form an oil film on the metal surface to resist the effect of low temperature.

■ In addition to cleaning and diesel lubrication, a layer of lubricating oil can also be applied. Calcium-based grease or lithium-based grease is the best choice, because they have a very good role in maintaining the performance of all aspects of mechanical equipment, and when used again, these oils will be better removed.

A gantry crane is similar to a bridge crane, but instead of moving on suspended runways, the crane uses legs to support the bridge, trolley, and hoist. These legs travel on rails or on the tires.

Gantry cranes are mainly used outdoors, but can also be used indoors. The gantry crane is ideal choice when you need a lightweight and quick knockdown crane for applications that require portability. It is also considered when there is a reason not to use overhead runway system and are most traditionally used in outdoor applications where full beams and columns can’t be installed, or they can be used below an existing bridge crane system. Gantry cranes are usually found in shipyards, railway plants, special construction sites like where a bridge is being built, or in places like steel mills and so on.

Copyright © Henan Sinomac Industrial Co., Ltd. All Rights Reserved.