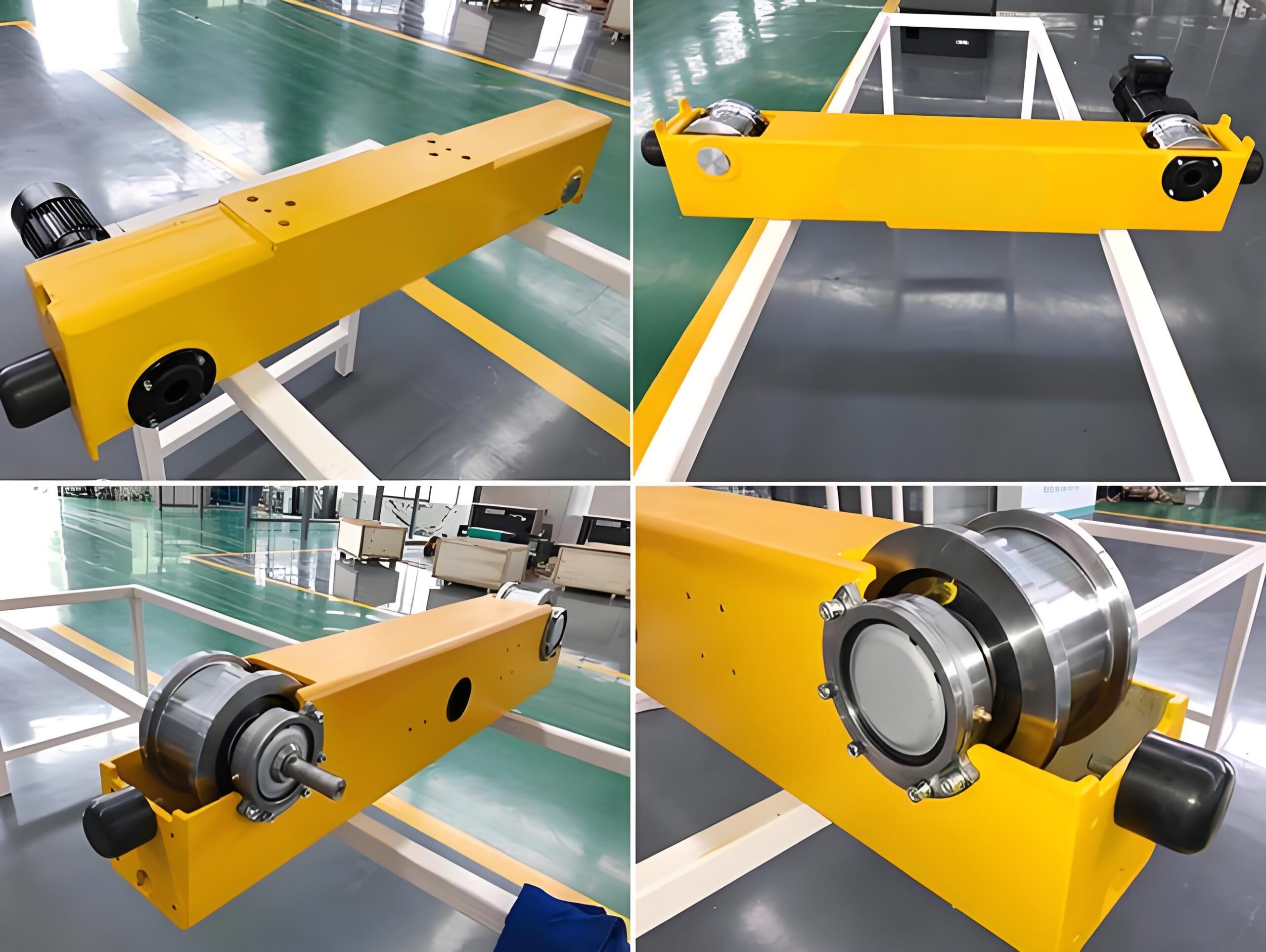

Crane End Carriage

Crane Parts Service

- Design Standard: DIN/FEM

- Motor Type: 3-IN-1 Geared Frequency Motor

- Wheel Type: Forged Wheel

Overhead Crane,EOT Crane,Gantry Crane

Description

Sinomac Industrial(SANOMAC) crane end carriage is made of high-strength steel and alloy steel, it has sufficient rigidity and stability. Its design supports a variety of installation methods, adopts high-precision processing technology, and has the advantages of light weight, high adaptability, low noise and long-lasting durability.

The various combinations of 4 wheels,8 wheels, and 16 wheels will be satisfied with different max wheel pressure.

Features & Advantages

The European End Carriages is a key component of the European Type cranes, which mainly bears the weight of the main girder and the weight of the lifted material, and drives the crane to move. Its main advantages as follows:

- Thickened Rectangular Tubes

This high-strength steel ensures that the end beam has sufficient rigidity and local stability, which is essential for bearing heavy loads and maintaining structural stability.

- Material of Wheels: High Strength Alloy Steel 42CrMo

These materials have excellent load-bearing capacity and wear resistance, ensuring long-term stable operation of the crane and reducing maintenance requirements.

- Output shaft of the reduction motor is directly connected to the wheel using DIN5480 splines

This design improves transmission efficiency and reliability, and is faster to install. The use of overclocked motors further improves power efficiency and operating performance.

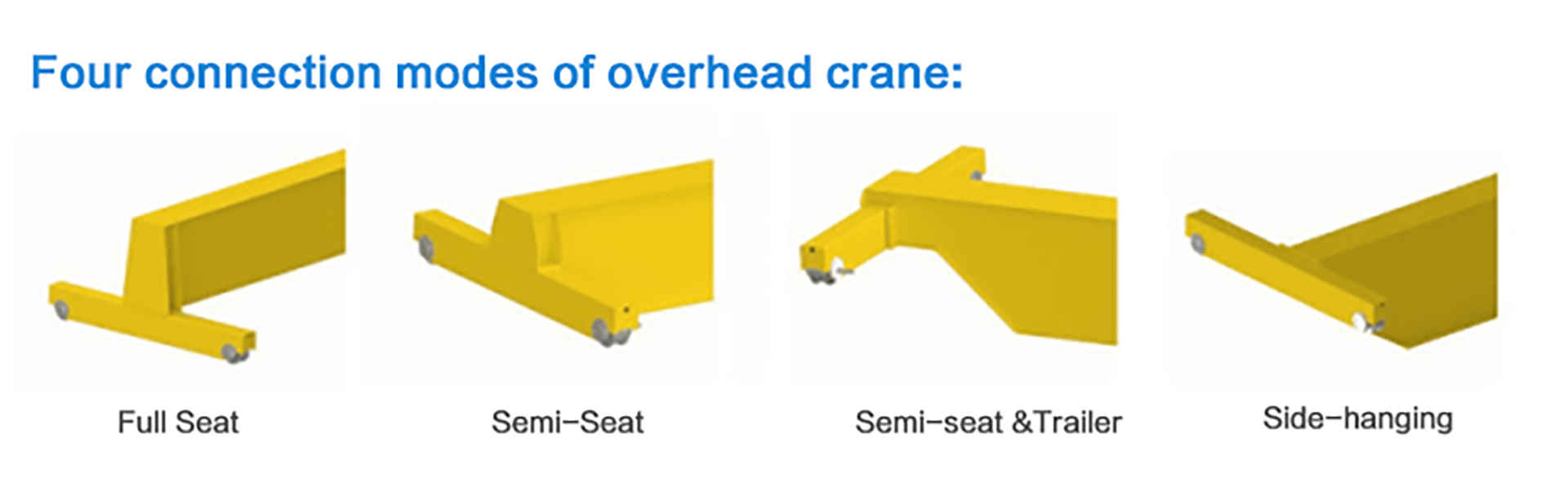

- Diversified Installation Methods

The end carriage design supports a variety of installation methods, including top connection, side connection, and top plus side connection to adapt to different plant structures and space requirements, increasing the applicability and flexibility of the crane.

- High Precision End Carriage Processing

The use of special combined machine tools for processing ensures high processing accuracy and beautiful appearance, thereby improving the quality and appearance of the overall machinery.

- Light Weight Design

Through efficient materials and design, it is possible to reduce the weight of the end beam, helping to reduce overall energy consumption and improve operating efficiency.

- Highly Adaptable

The design of the end beam may enable it to adapt to different operating environments, such as high temperature, high humidity or corrosive environments, expanding the range of use.

- Low Noise & Low Vibration

The optimized design reduces noise and vibration during operation, improves operator comfort and reduces the impact on the surrounding environment.

- Ease of Maintenance and Replacement

Design considerations may make the end beam easier and faster when maintenance or parts need to be replaced.

- Built to Last

The durability and longevity of the end beams are significantly improved through the use of high-quality materials and precision machining.

SIMILAR PROJECT CASES

Sinomac Industrial(SANOMAC) is a professional hoist & crane system slolutions provider.